|

BRAUMAT

Function

description

EQM

Equipment-Module

Highly flexible CIP-Program

|

BRAUMAT

based on S7-400 and S7-1500

|

|

Introduction

The

CIP program is very flexible. Most of the settings can be done in the

recipe, but the recipe has to be adjusted according the requirements.

Most of the Programming is in the Unit-FB, the EOPs are almost empty.

The

application was used for Centro-Brewery Mexico

Features

Highly

flexible CIP-Process, most of the settings are Recipe-based.

Maximal

Transparency as Transition and actions can be monitored online.

The

basic-recipe can be easily extended by copy and paste to more or

other cleaning-Agents.

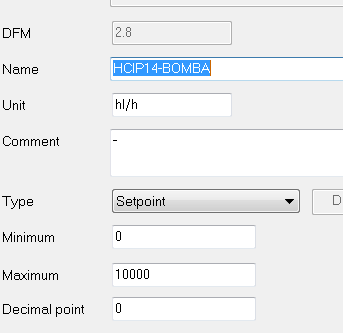

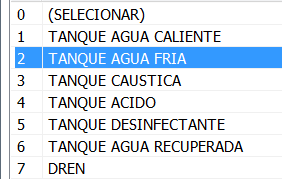

Source-Tank

and destination based on Recipe-Settings by DFM.

Transition-Conditions

(also combination) based on Recipe-Settings by DFM-Matrix.

Recipe-Options

like Bypass, Drain etc. based on Recipe-Settings by DFM-Matrix.

Minimal-Time

for transition by Recipe-Timer

Optional

function to switch off by Maximal –Step-Time by

Monitoring-Time and switch to A- in order to switch off all Output

and reset the Monitoring-Time. Manual restart is required.

Delay

for Transition by Conductivity to avoid reaction on bubbles or short

changes.

Optional

switch for circulation times only start if Temperature and

conductivity is ok.

Integrated

Pipe or Tank-empty-detection by the return flow with integrated

delay.

Automatic

switch-over to Drain if the Tank is full.

Interlock

of the Inlet-valves with Tank full is mandatory.

The

operator can input the dynamic Data by Process-Parameters. The

recipe itself should be changed only by skilled people.

Sandwich-principle

integrated. In order to save hot water after hot caustic first hot

water, then cold water will be used.

Saving

water by switching optimized to the stable water tank.

Ensure

that during circulation the Tank is emptied from time to time.

Maximal

using Recovery water for the process.

If

the Tank is empty it is automatic switched over to Drain.

If

RCS is used

Centralized

settings for the RCS-Data like Function-ID etc.

Checking

the Routes by RCS-feedback. So no extra request is necessary.

The

Outlet CIP is one location, Tank x another, Return CIP Location 3.

In

each relevant step Source and Destination-ID is transferred to RCS

and can be changed.

In

the Unit FB all RCS-stuff is programmed and activated by an

interface flag.

Hold

and Resume is by A-; The flag A- M 102.0 can be triggered as well by

other functions.

Disable

transition is by Flag M 101.5 “add. Device”.

Use

flag M102.0 for to enable the Unit monitoring time.

Integration

There

is a version with RCS and without RCS.

Critical interlocks

should be considered.

CIP

uses FC1450….1458

FB1099

is relevant and DB3098.

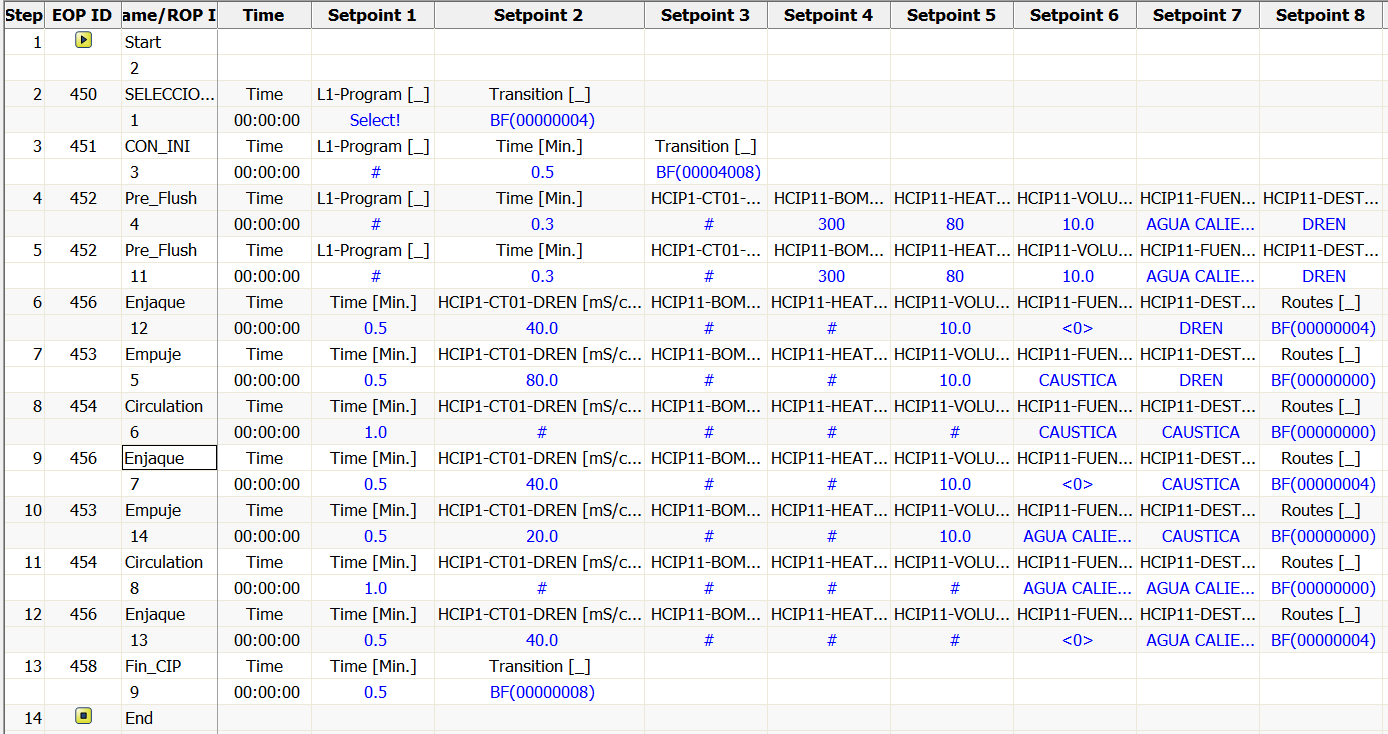

In the EOPs you only need to

activate one flag and check for another flag, that’s it.

This

is one template-recipe

Procedure

Preflush

Water with Route Prerun by time.

Preflush

Water with Circulation to Drain by time.

Empty

Tank to drain by Empty-detection

Push

Caustic to Drain until mS is ok

Caustic

circulation by Time

Empty

Caustic by only return open by Empty-detection

Push

Hot-Water until Caustic is in Tank by mS-detection

Water

circulation by Time

Empty

Tank by Empty-detection

With

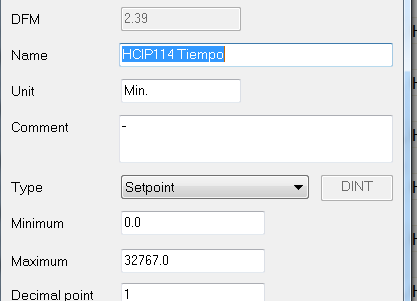

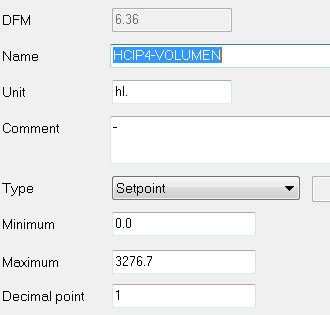

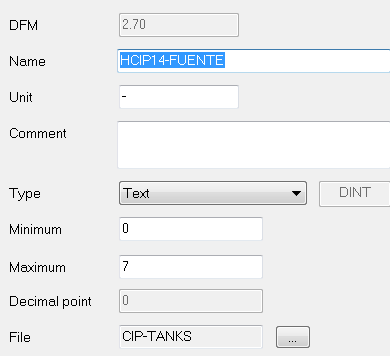

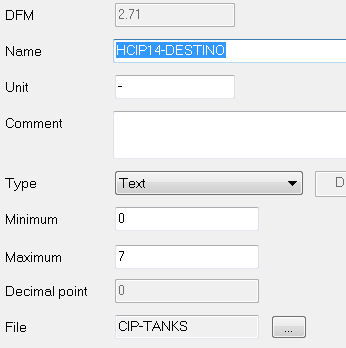

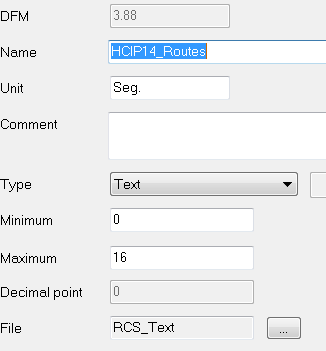

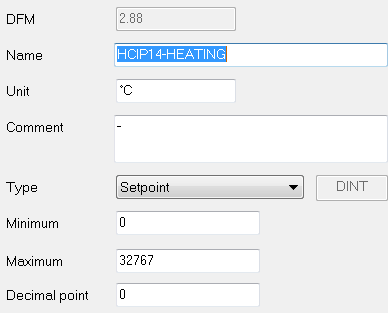

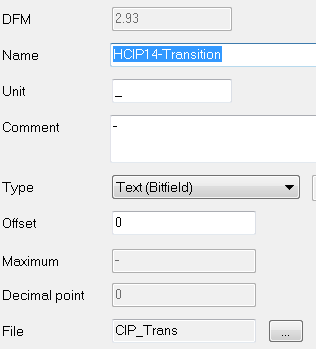

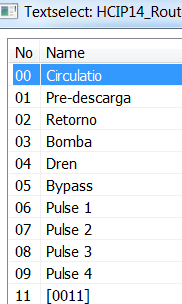

the DFMs

DFMs

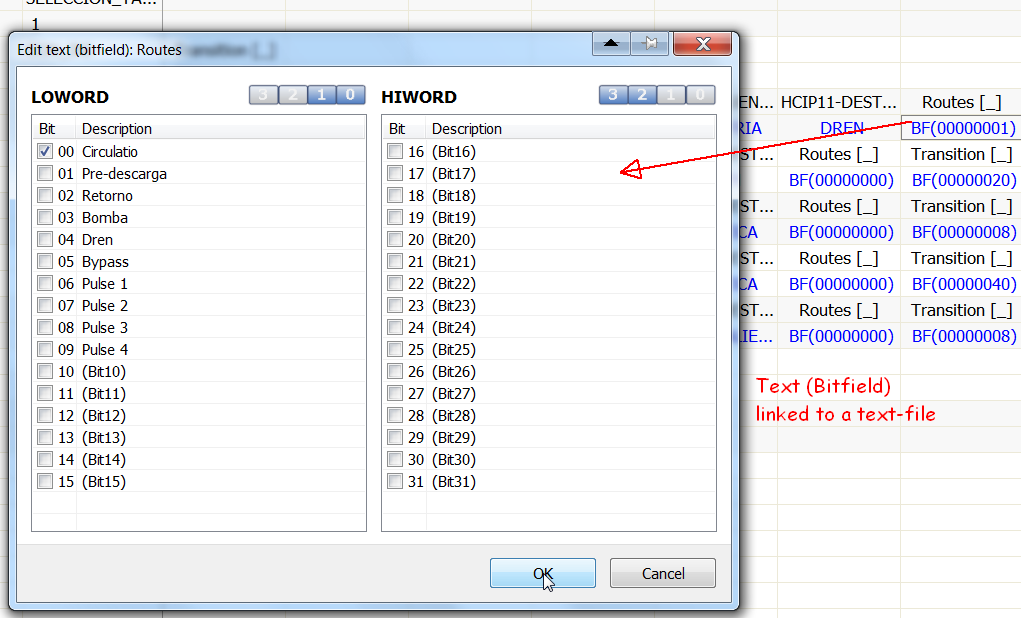

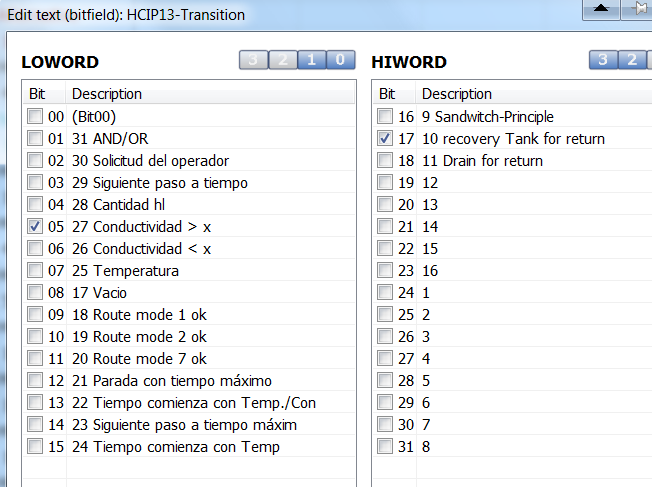

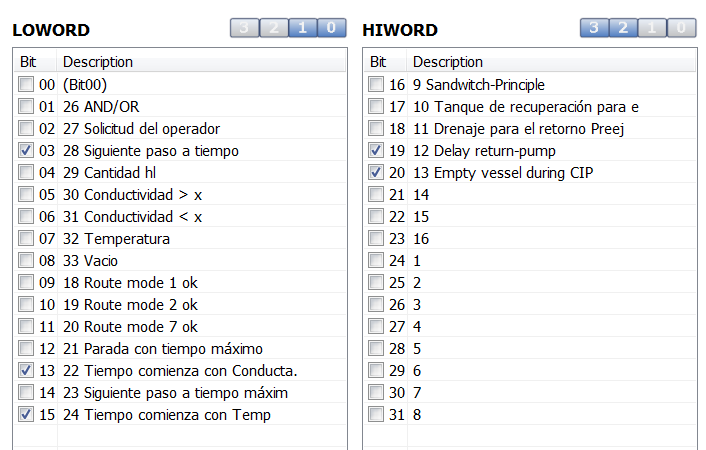

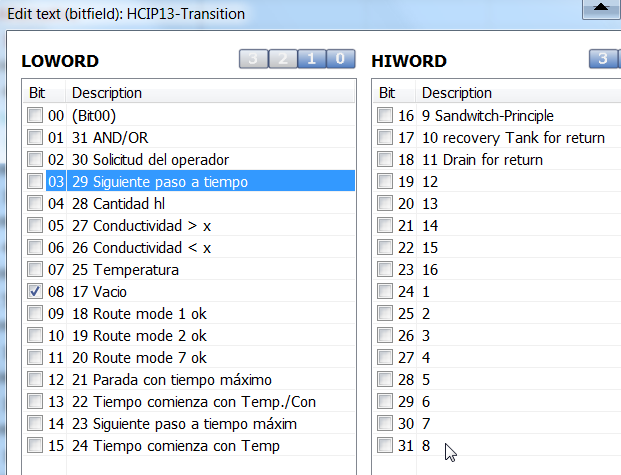

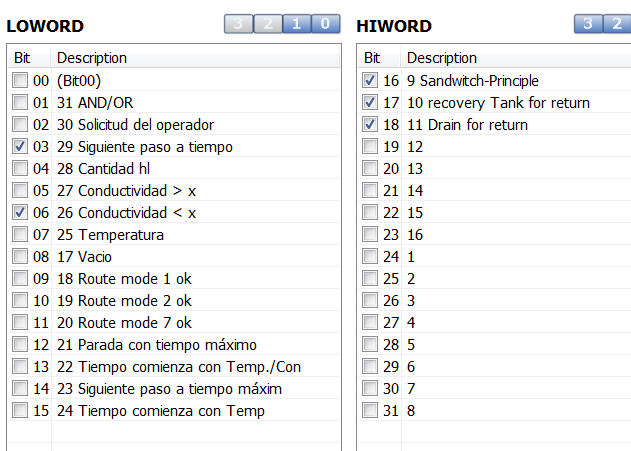

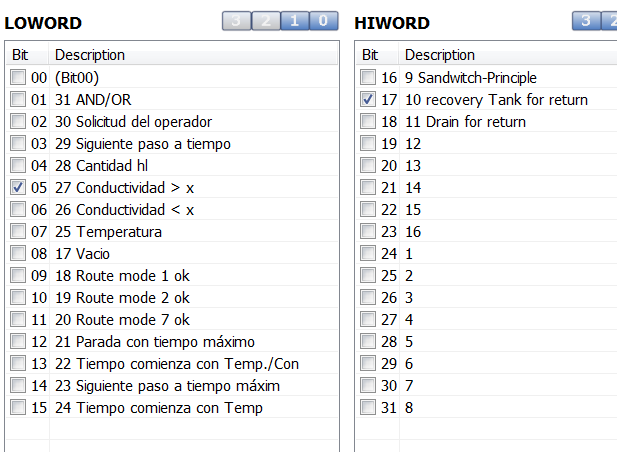

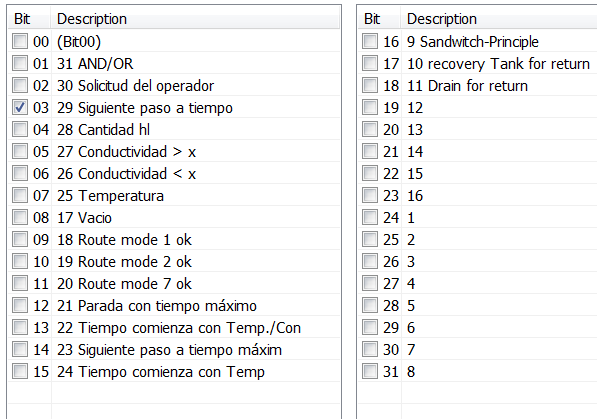

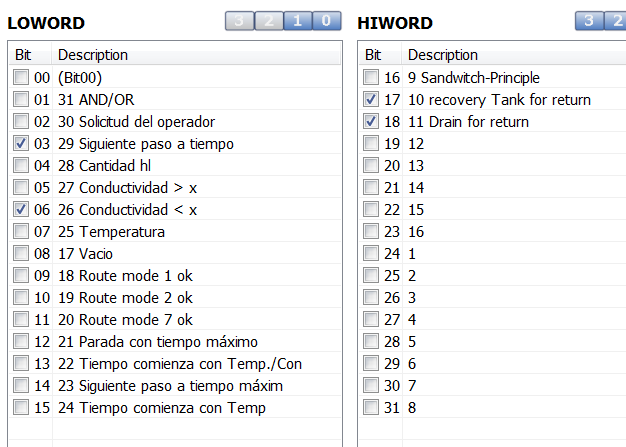

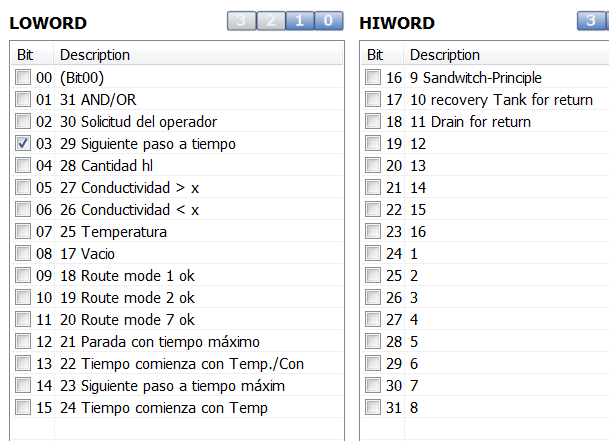

The

selection of the Route-options must defined as Bit-field with

Decoder-Number 1

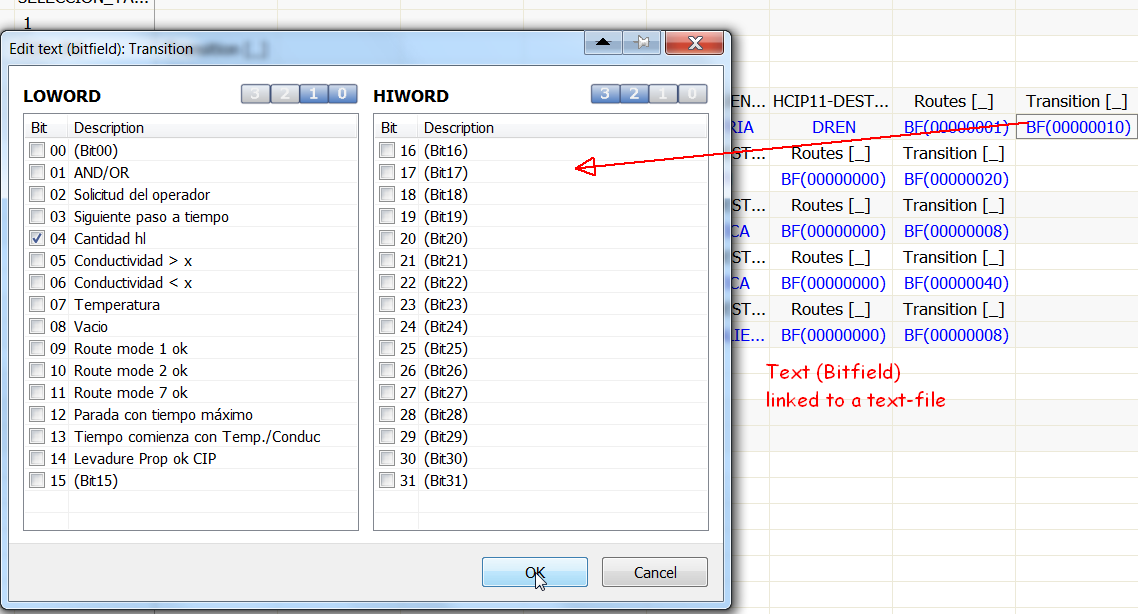

The

selection of the Transition must defined as Bit-field with

Decoder-Number 2

Source

and destination

Source

and destination

Route-Options

Route-Options

Running

CIP

Start

CIP Yeast-Propagation Tanks or line first.

Then

the CIP-Program CIP Station 1 Line 1.

Select

the proper Program in Step 1 and confirm.

If

A- is pressed in one Unit, it will be transferred to the other Units

as well.

For

YTL CIP start YPL CIP and select in Step 1 YTL CIP.

Procedure

and Transition

step

selection program only Operator request

Step

Preflush with water by quantiy

Empty

Tank (only for Tank-CIP)

Step

Prerun Caustic, by conductivity, go to Recovered water

Circulation

hot caustic by time. Time start when Temperature and conductivity is

ok; Optional ensure that the tank is emptied from time to time.

Empty

vessel (if it is a vessel-cleaning)

Return

Caustic with Conductivity and switch Drain and Recovered water. Make

sandwich principle.

Prerun

Acid, push the water out by conductivity

Acid

circulation by time

Return

Acid by conductivity, switch to Recovered water and Drain

Cold

water circulation by time

Attachment

Text-file

English (the number reflects the decoder-number)

26

AND/OR

27

Solicitud del operador

28

Siguiente paso a tiempo

29

Cantidad hl

30

Conductividad > x

31

Conductividad < x

32

Temperatura

33

Vacio

18

Route mode 1 ok

19

Route mode 2 ok

20

Route mode 7 ok

21

Parada con tiempo máximo

22

Tiempo comienza con Conducta.

23

Siguiente paso a tiempo máximo

24

Tiempo comienza con Temp

9

Sandwitch-Principle

10

Tanque de recuperación para el retorno

11

Drenaje para el retorno Preejecución de

12

Delay return-pump

13

Empty vessel during CIP

14

15

16

1

2

3

4

5

6

7

8

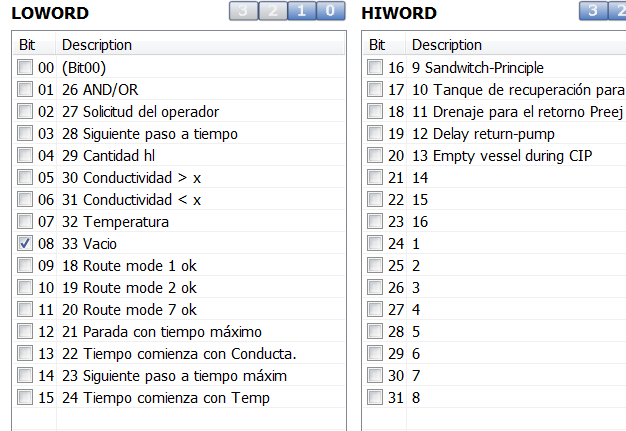

Textfile

Spanish

31

AND/OR

30

Solicitud del operador

29

Siguiente paso a tiempo

28

Cantidad hl

27

Conductividad > x

26

Conductividad < x

25

Temperatura

17

Vacio

18

Route mode 1 ok

19

Route mode 2 ok

20

Route mode 7 ok

21

Parada con tiempo máximo

22

Tiempo comienza con Temp./Conducta.

23

Siguiente paso a tiempo máximo

24

Tiempo comienza con Temp

9

Sandwitch-Principle

10

recovery Tank for return

11

Drain for return

12

13

14

15

16

1

2

3

4

5

6

7

8

|