Braumat

Tipps and Tricks all Versions

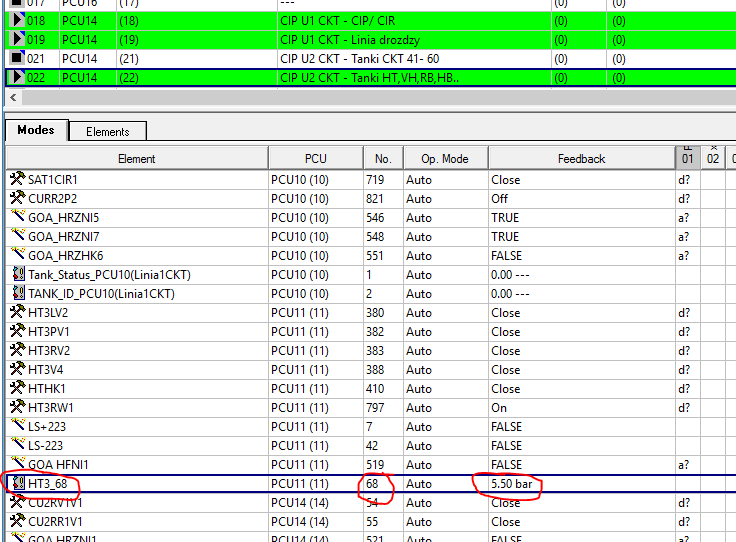

1Recipe-Structure

Area

(different PCU’s):

Brewhouse

Fermentation

Filtration

Recipe-Category,

Recipe-Type

Production

CIP

Recipe-Nr,

Master Recipe

Pils

Export

Singha

Sequence

-> MTK, Lauter Tun, Fermentation-Tank, = Unit, RUP

MTK

Lauter

Tun

Wort

Kettle

Tank

1

Tank

2

FB1001

(Sequ 1), FB 1002 (Sequ 2) ……; always running all 1-Sec

DFM-Activation,

Sequence-Timer, Permanent Condition, etc etc.

Steps:

GOPs, EOP, ROPs, Phase, Control Strategy, SFC, SFC-Type

f.e.

Start-up, Heating, Rest,

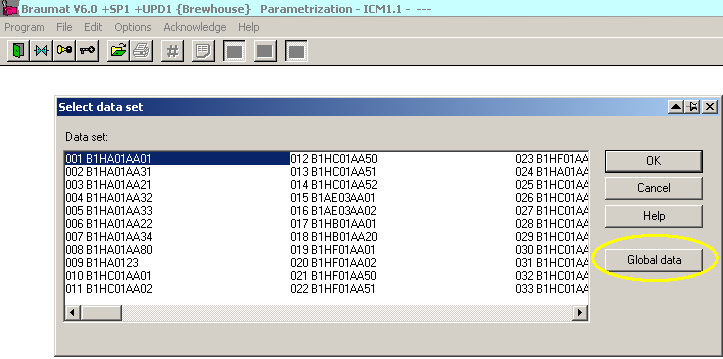

FC1001,

FC1002, FC1003 etc 2999

Start Step-Time, activate ICM (Motor,

Valve), check for next-Step-Condition (Transition)

Setpoints:

DFM (Digital Function Module)

->

Setpoints, Timers, Decoders, Counter

Copy

an existing Recipe to a new one

Make

a new Master-Recipe

but

only the Header (first Page);

Press the button

to

open the next window. Select Recipe-Category “Production”

and save it.

to

open the next window. Select Recipe-Category “Production”

and save it.

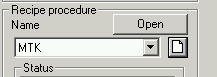

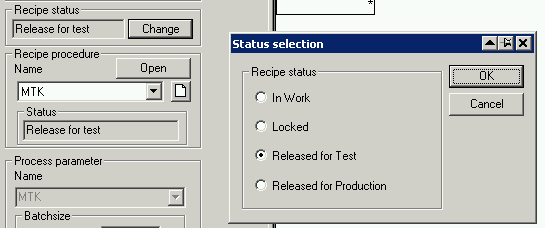

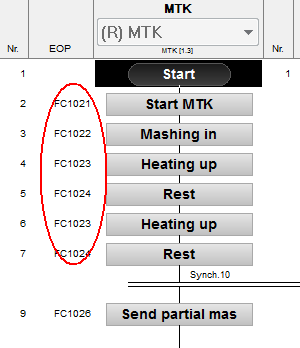

After

close select again the “Recipe-procedure” to MTK like

here:

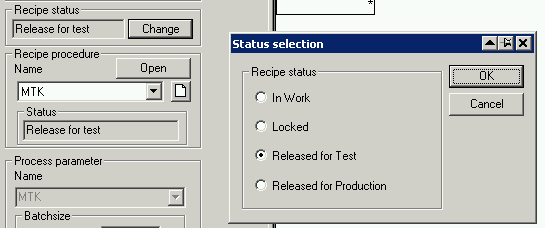

Save

and close the Recipe and select the Recipe-Status to “Released

for Test”

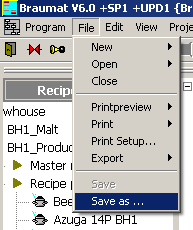

Then open

existing recipe and select “Save as” to the new recipe

(at the end of the list) Save; Close Recipe and open again.

Making a new Recipe

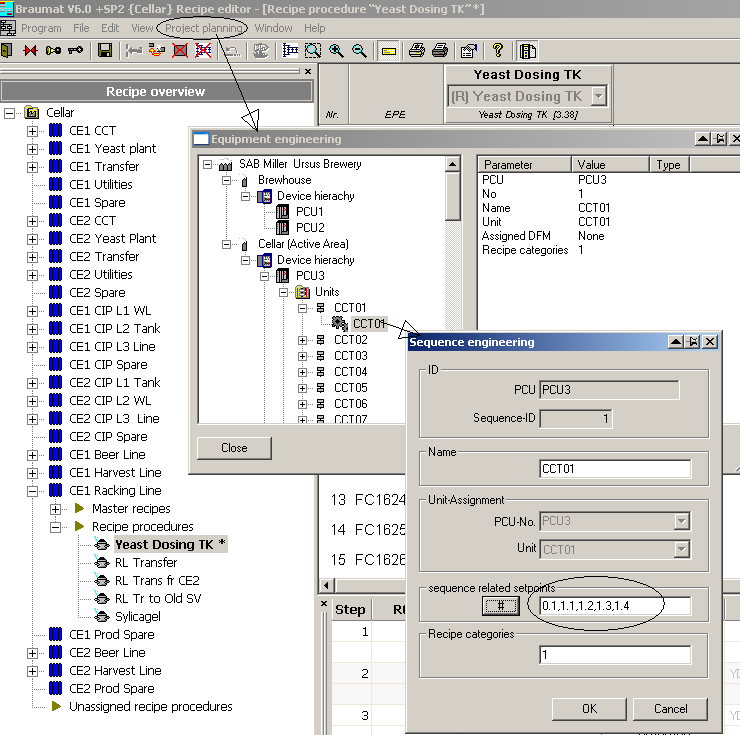

First

go to Parameterization Sequencer

Define

your Sequence-Name

Manual

Group (Sequence 1 = Manual group 1 for example)

Time_Rel

(Flag for Monitoring-Time f.e. M 1.0; Enable the Timer used in

FB1001… for to enable the Monitoring-Time)

Set

the BA_Year to “0”

Go

to Parameterization DFM0.1

Define one counter (Name = Counter) with Art=0 and Increment of

1

Go

to Parameterization DFM1.1 and DFM 1.2

Define one DFM1.1 for Time

(Data-Set-Name) with Art=1 Up-Counter

Divider = 6 (all 6

seconds)

QBit: M 10.0 Enable the Timer used in FC1001…

for to enable the Time)

Define

one DFM1.2 for Setpoint

(Data-Set-Name = Level) with Art=4 Limit-Value

PSK = 5

for Hysteresis of 5

QDat: AIN,1, XIST: Source actual

value of Analog In 4

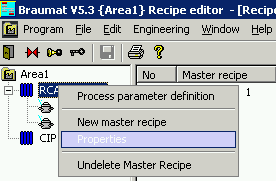

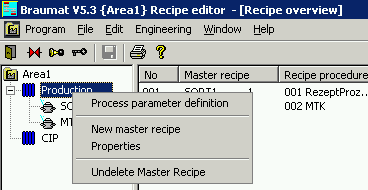

Select

Basic-Menu Process-Administration, Recipe,

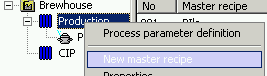

Right click on RCAT1

Rename

to Production

Right

click on Production

Select:

New Master Recipe or double-click on a existing one

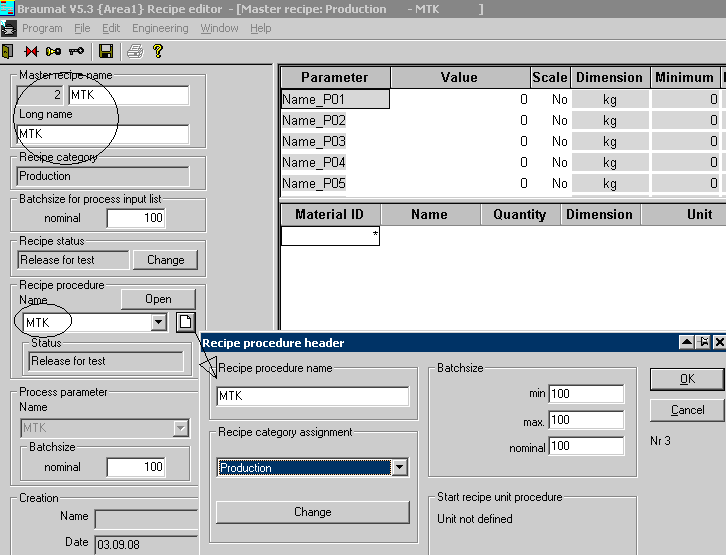

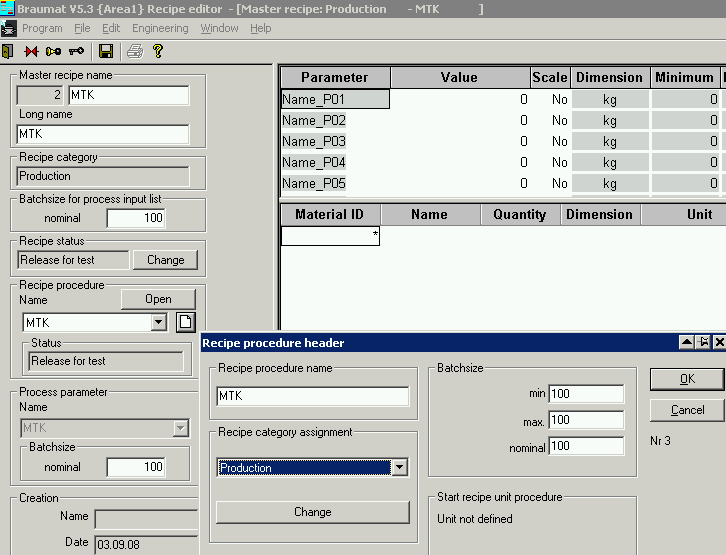

In

the next Window make the Settings for a new Recipe like this

Press

the button

to

open the next window. Select Recipe-Category “Production”

and save it.

to

open the next window. Select Recipe-Category “Production”

and save it.

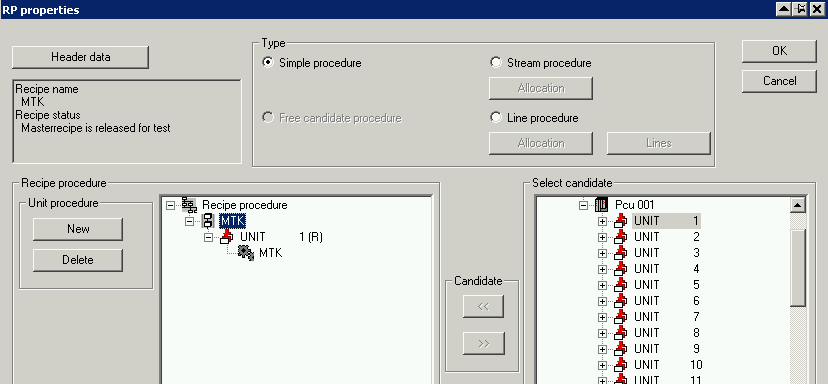

After

close select again the “Recipe-procedure” to MTK like

here:

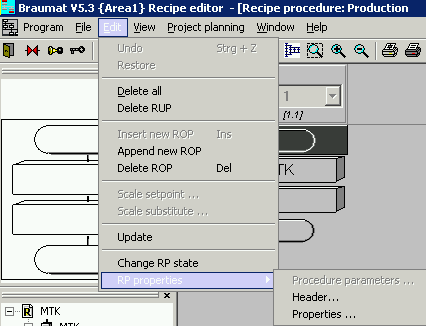

Then

open the Recipe, a window will Pop up or you have to Select Edit,,

RP-Properties, Properties:

Select

New and enter “MTK”;

Then

click on the lift Side MTK and on the Right side Unit 1.

Put

the candidate by << to left and press ok.

Select

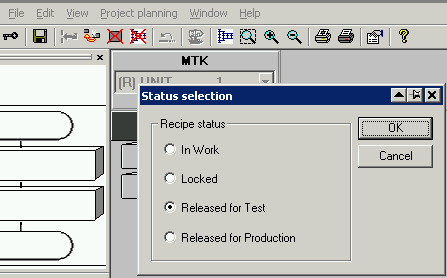

Edit, change RP-Status and select Released for Test

Then

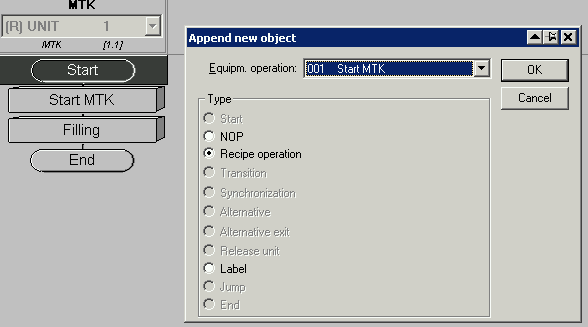

select Edit and Append new ROP, Select “Start” if it is

possible

If

there is a NOP-Operation on Top, double click on it and select

“Start”

Select

the last Step, then again “Append new ROP”

Select

Recipe-Operation 1 (1.EOP Refers to FC1001)

Select

the last Step, then again “Append new ROP”

Select

Recipe-Operation 2 (2.EOP Refers to FC1002)

Select

the last Step then again “Append new ROP” End

Delete

with right click what you do not need

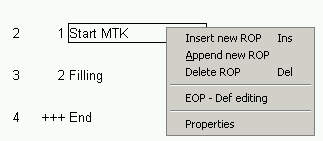

Then

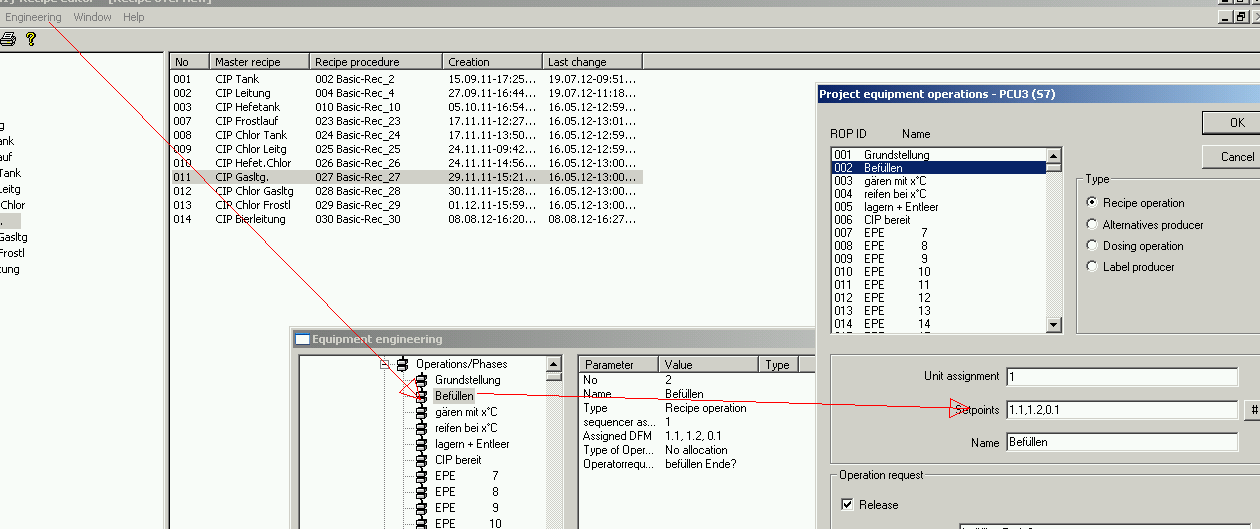

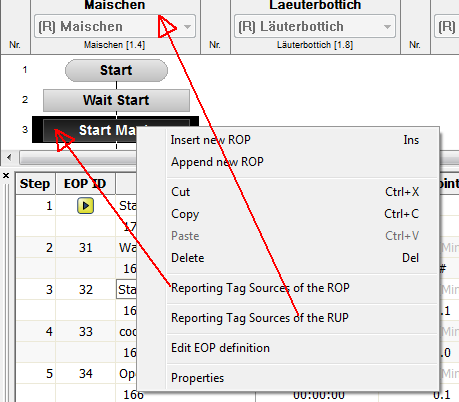

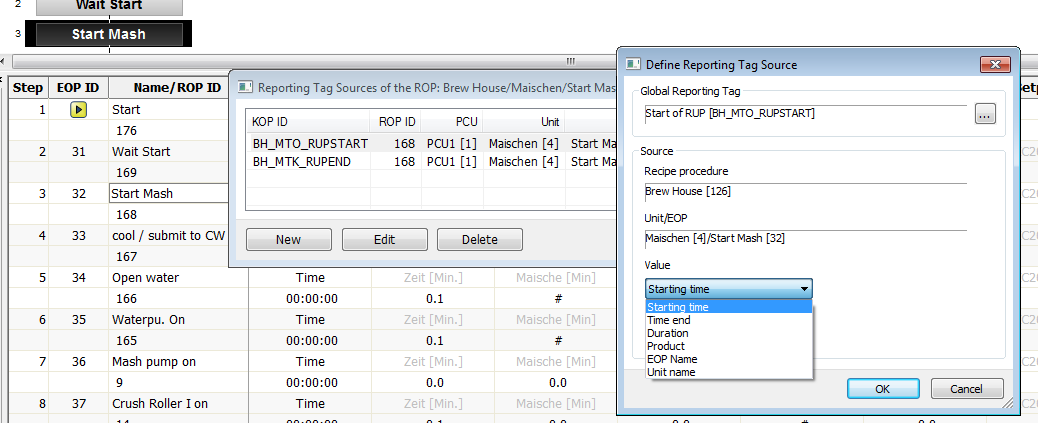

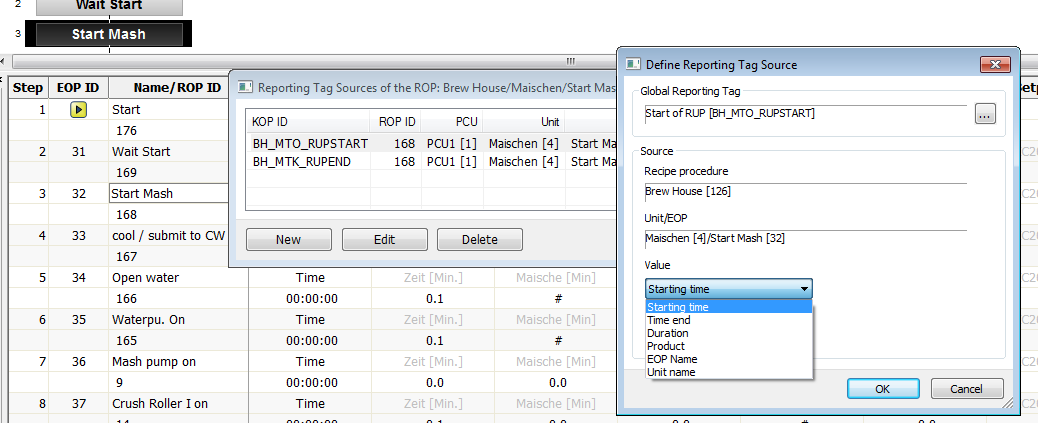

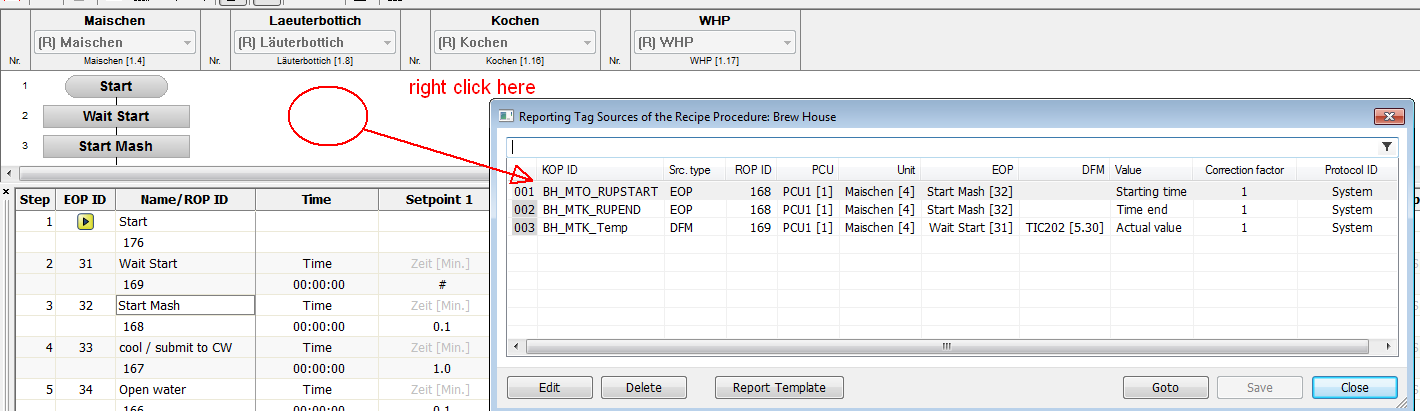

right click on the ROP and select EOP-Def editing like this

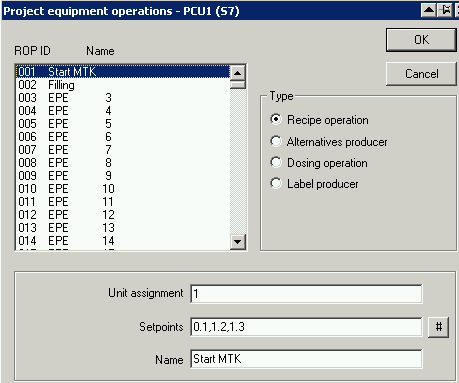

Make

“Unit assignment” to 1 means Sequencer 1

Press

“#” to select the according DFM 0.1 (Counter), DFM1.1

(Time) and DFM 1.2 (Level)

Give a Name for the Step “Start

MTK” for example

Do

the same for the following step “Filling” for example

Right

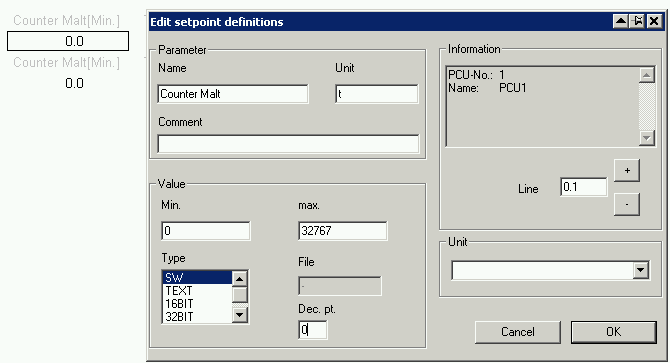

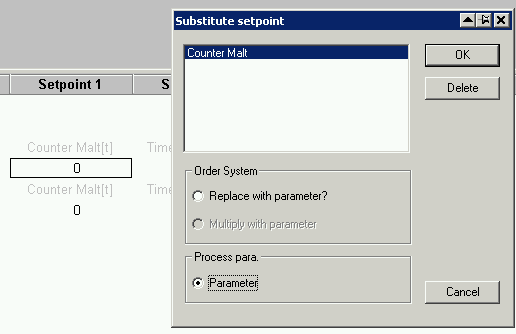

click on the DFM in the Recipe and select “edit SP-Def”

Fill

the window like that for the counter and Time (Dec-pt = 1) and Temp

(Dec-pt = 1)

Save

and close the Recipe and select the Recipe-Status to “Released

for Test”

Save

and exit Recipe-Editor

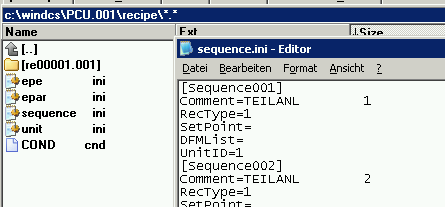

Go

with the Explorer to d:\windcs\PCU.001\recipe\Sequence.ini

and

open Sequence.ini and Assign Sequence 001 to RecType 1 (Category from

the Recipe Editor) and Save.

Do no forget to do the same for new

Sequences!

RecType

corresponds to the “1” for Production and “2”

for CIP for Example (see below)

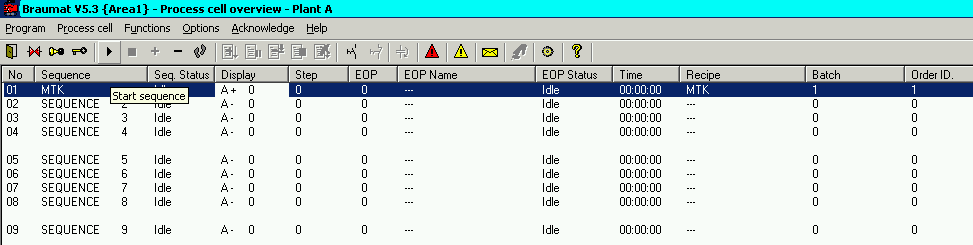

Go

in the Basic-Menu to Process-Monitoring and Sequence-Control

Press

the start-Button for the according Sequence 1

Enter

Batch-Number and Ordernumber and select your Recipe (Masching)

You

can modify the list for the Sequence at Functions, Edit Process Cell

view

1

1 means PCU Nr. 1, Sequence-Nr 1

1

2 means PCU Nr. 1, Sequence-Nr 2

You

can make groups in the File Functions, , Edit Process Cell

(Bereich.txt)

If

you want to define Process-Parameters

Right

click on on the Recipe-Category “Production” and select

Process parameter definition

Then

select the DFM’s you need and shift them to the right side!

Then

right-click on the DFM in the Recipe and select Substitute Setpoint

and Process-Parameter.

But

to Start the Recipe the Setpoint should be > 0!

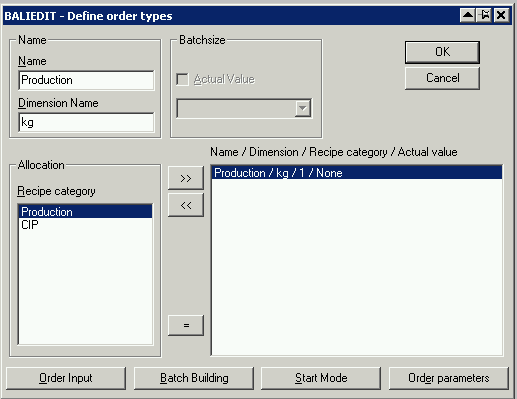

Order-System-Setup:

Open

the batch-scheduler and select File Close

Then

Select Project-Planning, “Order-Types”

Move

what is in the right Window to the left and Edit Production on Top

Then

Select at “Recipe-Category” Production and shift it to

the right

Then

it looks like this:

Now

you can select Order-Input etc. and Setup all Parameter!

At

Order-parameters you can select DFM’s which will be transferred

(the Setpoint by starting the Order-System) to the Recipe (select

Substitute Order-Parameter in the Recipe)

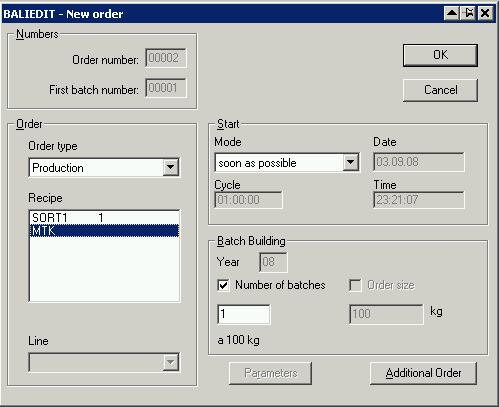

Close

the Window, and Select Edit, “new Order” and Select the

Recipe.

After

you press ok, you have the Recipe in the List.

You

can select it and release it, the Sequence will be started!

Here

we go!

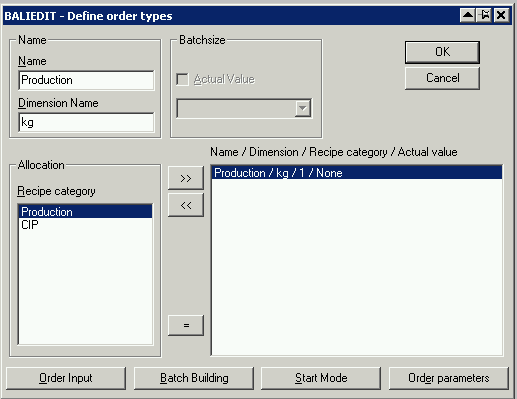

online-recipe

for

to see recipe online (key F9 in sequence-overview or from the

faceplate) you need to define the Recipe-Type in the order system

Open

the batch-scheduler and select File Close

Then

Select Project-Planning, “Order-Types”

Move

what is in the right Window to the left and Edit Production on Top

Then

Select at “Recipe-Category” Production and shift it to

the right

Then

it looks like this:

Now

you can select Order-Input etc. and Setup all Parameter!

Program-Structure

FB1200

Cold Restart (never make a cold restart, all Parameters will be

deleted!)

FB1201

Warm Restart (here you program pre-setting-values)

OB1

Call

FB1220

Braumat-Code

Call

FB1221

BE

OB35

(100 ms)

Call

FB1222

Call

FB1224 User-FC/FB (f.e. Call FC 410)

Braumat-Code

Call

FB1223

BE

All

1-Second

FB1225

Unit-related

(1 second)

FB1001

Unit 1

FB1002

Unit 2

FB1003

Unit 3

FB1004

Unit 4

….

FB1064

Unit 64

Steps

(GOPS)

FC1001,

1001, Step 1,2 ....

Interlock

FB1226…FB1233

Free

Protocol

Make

a description of your Dbase-File in File FRPROT\FEPR_DEF.DEF

424

1

AUFTR_NR CINT 5 Auftrags-Nr.

6

CHARG_NR CINT 5 Chargen-Nr.

11

SZ_JAHR CINT 2 Startzeit Jahr

13

SZ_MONAT CINT 2 Startzeit Monat

15

SZ_TAG CINT 2 Startzeit Tag

17

SZ_STUNDE CINT 2 Startzeit Stunde

19

SZ_MINUTE CINT 2 Startzeit Minute

21

SZ_SEKUNDE CINT 2 Startzeit Sekunde

23

REZ_TYP CHAR 16 Rezepttyp-Name

39

REZEPT CHAR 16 Rezept-Name

55

TEILTEL CINT 6 Teiltelegramm-Nr.

61

BEDIENER CHAR 16 [1,1,0,1,"bedien.txt"]

//PCU1,Tt.1,1.DW, 1 Dataword

77

SORTE_1 CHAR 16 [1,1,1,1,"sort1.txt"] //PCU1,Tt.1,

2.DW, 1 Dataword

93

SORTE_2 CHAR 16 [1,1,2,1,"sort1.txt"] //PCU1,Tt.1,

3.DW, 1 Dataword

109

SORTE_3 CHAR 16 [1,1,3,1,"sort1.txt"] //PCU1,Tt.1,

4.DW, 1 Dataword

125

DATEN1_5 CINT 6 [1,1,4,1] //PCU1,Tt.1, 5.DW, 1

Dataword

131

DATUM_S1 CHAR 16 [1,2,0,3,"DT1"] //PCU1,Tt.2, 1.DW, 3

Dataword

147

DATUM_S2 CHAR 16 [1,3,0,3,"DT1"] PCU1,Tt.3,DW21

163

DATUM_S3 CHAR 16 [1,4,0,3,"DT1"] PCU1,Tt.4,DW31

179

START_ANS CHAR 16 [1,5,0,3,"DT1"] PCU1,Tt.5,DW41

195

START_FIL CHAR 16 [1,6,0,3,"DT1"] PCU1,Tt.6,DW51

211

ENDE_FIL CHAR 16 [1,7,0,3,"DT1"] PCU1,Tt.7,DW61

227

START_VL CHAR 16 [1,8,0,3,"DT1"] PCU1,Tt.8,DW71

Etc

call

the FB580 for to Transfer the Data

CALL

FB 580, DB580

iPartTeleNr:=1

(here for next Block 2,3...)

iBatch

:=0 //Batch Data is coming from the current Data-Set

iOrder

:=0

iRecipe

:=0

iRecType

:=0

iDataDest

:=1 //1. Dataword (-1=5DW)

iFunction

:=7 // Function = 7, that is load block data word

block

iANA

:=0

rRealInput

:=0.000000e+000

iDBNr

:=10 //DB-Number

iStartDW

:=1 //Dataword

boRetVal

:=M2000.0 //Error return value; 0: no error; 1: Error

next

Data-Wort, max 5!

CALL

FB 580, DB580

iPartTeleNr:=1

(here for next Block 2,3...)

iBatch

:=0 //Batch Data is coming from the current Data-Set

iOrder

:=0

iRecipe

:=0

iRecType

:=0

iDataDest

:=2 //2. Datenwort (-1=5DW)

iFunction

:=7 // Function = 7, that is load block data word

block

iANA

:=0

rRealInput

:=0.000000e+000

iDBNr

:=10 //DB-Number

iStartDW

:=3 //Dataword

boRetVal

:=M2000.0 //Error return value; 0: no error; 1: Error

….more

till max 5 Dataword

then

send it to IOS

CALL

FB 580, DB580 //send Data

iPartTeleNr:=1

iBatch

:=0

iOrder

:=0

iRecipe

:=0

iRecType

:=0

iDataDest

:=0

iFunction

:=0

iANA

:=0

rRealInput

:=0.000000e+000

iDBNr

:=0

iStartDW :=0

boRetVal :=M2000.0

==============================

Telegram

6 must be enabled in a FIFO 1 and 4

The

according DEF file must be defined in "windcs\sys\protdida.txt"

(you can take the preset values)

The

definition files must be created in "windcs\frprot" (see

section 2.7).

Fepr_xxx.def

xxx = recipe type (range = 1 to 255)

You can copy and edit the

fepr_def.def template file.

You

can have several different Protocols, depending from the

recipe-type, defined in windcs\sys\protdida.txt

For

making a Layout with MS-Access you need a full version of Access.

For

the Client to view the Data, the freeware Access runtime can be used.

Call

the MSI setup file from CD for to install Access runtime for

evaluation:

‘...\sis_sys.53\SISTAR.530_V0503xxxx\MicrosoftMS_AccessRuntime_Office_2003\Accessrt.msi’.

More

Hints

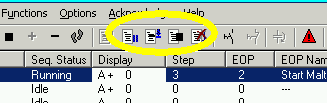

1.1Activate the S88-Commando:

Change in

c:\windcs\sys\seqctrl.ini: [MainWin]; EOPAdmin=255 and restart

Braumat.

Very nice Buttons specially the right makes “Step

+ 1”, sometimes useful.

Activate

Change Protocol

With

change protocol, all activities on the IOS are logged (change value

etc)

change in file

wincds\sys\PCU_SERV.ini

at [Recipeserver(&SoftCP)]

add

globlog.dll

like

this

Ports=ta.dll,s7.dll,h1_ndis.dll,recctrl.dll,balidata.dll,cas.dll,client.dll,globlog.dll

Change

in logging.ini:

EnableGlobalLogging=1.

change

here:

And

then it works only on the recipe-Server!

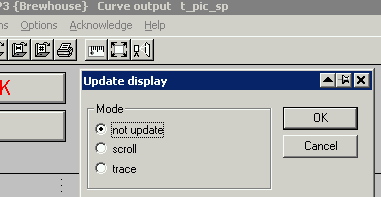

Trend

Export to text-File

In

Kurven.ini under Select:

_trace=1;

_Tracemode=A;

_traceval=1;

_tracevalmode=A (or W)

Then

in Folder \Tmp

kurven1.txt…

Data are generated when the Trend-Picture is opened.

But

in Curves the Switch must be in "Options, Display Mode, not

update”

Changing

the Menu, Add new Functions

In

Texte.10\Menuv460.ini;

But you have to change the number on Top

as well

1.2Starting Programs Time-Planned or at the beginning (f.e.

Trendmanager)

In

PCU_Serv.ini search and change to

;Start

and Check for running of ProcessScheduler "ProSched.exe"

RunProcessScheduler=1

Then

modify windcs\sys\ProSched.ini

[Global]

Processes=trendman

[trendman]

Application=d:\windcs\sys\trendman.exe

;Start

this application if not running and check for

running

Type=PERMANENT

;At

own shutdown, shutdown altough this application

ShutDown=1

1.3Trigger the curves

Declare

measured value in "Trending definition"

Chose

iID is 54 for FB1054 and 59 for FB1059 but take care that this

GroupID is not yet used by others.

Restart

the Trend manager only or restart Braumat completely.

Then

write codes in FB1054 (cip Filler, sequence 54) and in FB1059 (cip

Filter, sequence 59)

Start and Stop of Curves

Call

the FC 695 for

Start of Logging

and this for

Stop of logging

but

just once with a Flag (M102.2 or M102.3); ID = Group-Number.

So

just put this to the Sequencer-FB:

CALL

"TRIGG_CURVE_GR_FC"

boRUN

:="SEQU_Run" //M 102.1

boACTSEQ

:=TRUE

iID

:=xy //curve-group

iSEQID

:=0

byRECCAT

:=B#16#0

byYEAR

:=B#16#0

iORDER_NO:=0

iBATCH_NO:=0

iRECIP_NO:=0

Then

make a Trend-image and select according values

Some

information about setting up a Server or a Client.

Install

Braumat from the CD on a new Server or Client (on C:\ or D:\-Drive

or other)

Copy

a running Windcs-Folder to \Windcs (overwrite all!) or just rename

the original one and copy all \Windcs.

To

register OCX call c:\windcs\sys\ocx\ register.bat

Adapt

in c:\windcs\sys\trendman.ini if C:\Drive: 4$\\PC-Name\C\WINDCS

or

D:\Drive 4$\\PC-Name\D\WINDCS.

Start

Braumat and go to Administration, Configuration and change the

Site-Configuration, especially the name of your PC

Select

in the PCU-Server whether it is a Server or Client.

Restart

Braumat.

To

change Windcs from D:\

to C:\ or reverse

change in Windows, System-Settings, System, Advanced,

Enviroment-Variables, select down “Path” in the List and

“Edit”. Change C:\WINDCS\SYS to D:\WINDCS\SYS or reverse.

Then

go to the windows-Directory search the file win.ini, open it and

search Windcs and

change

C:\WINDCS\SYS

to D:\WINDCS\SYS

or reverse.

Restart

Braumat.

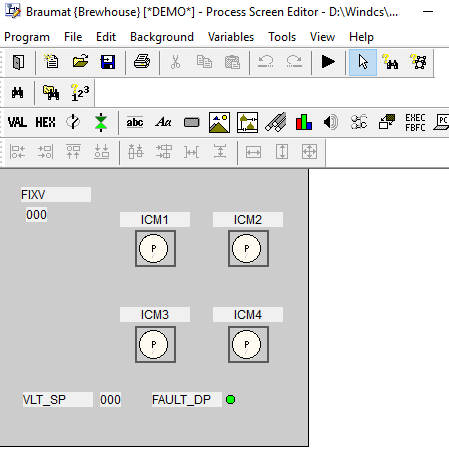

To

activate the

Demo-Version

Copy

c:\windcs\sys\PROD_DLL\ PROD32.DLL to c:\windcs\sys

After

8 hours you need a restart of Braumat. But there is not a message,

the functions do not work any more.

How

to Stop Braumat

and all the Services in the background (to rename the directory

Windcs for example)?

Call

c:\windcs\sys\terminator.exe

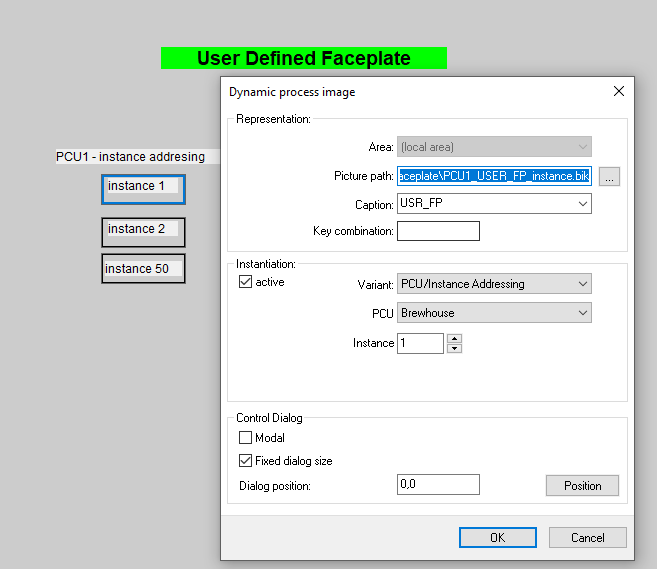

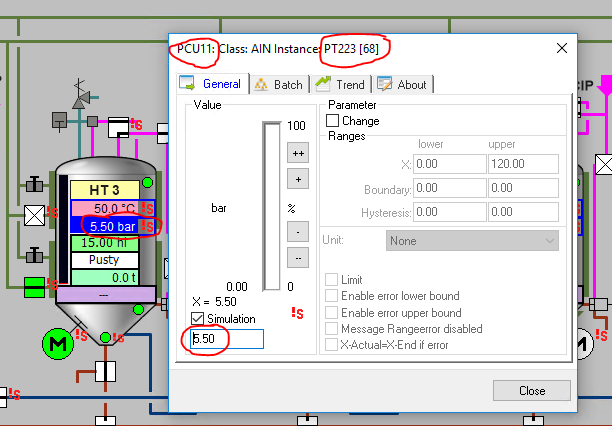

How

to extend the number of Instances (for example Analogue Input)

Extend

the DB to the according number of Data-Set by -Manager -Manager and

download. If there is already a Parameterization, save the content

first with the Excel-Productivity-Tool (after a upload of the DB).

Change

the number of Instances in the DB online and offline.

Change

the number of Instances in the files

c:\windcs\param.pcu\PARAMS7.010

for English S88

c:\windcs\param.pcu\PARAMS7.001

for English

c:\windcs\param.pcu\PARAMS7.000

for German

Here

a example for the 3 Step-controller:

object

ThreStep=DB744; (*Three-position controller*)

CID=CID_DREIP;

max=96->change

to 128 for example

offset=300;

Fast

ICM (50/100/200 msec)

In

order to have a fast ICM with 100 ms Cycle-Time for Feedback and

Output call

Call

FC727 with ICM-Number in the FB1224

iMode

:= 35 (35=OB35 = 100 ms, 36=OB36 = 50 ms, 34=OB34 = 200

ms)

V7:

FB1230: 200 ms

FB

1231: 500 ms

For

PCUs <V7, the synchronization errors resulting from direct calls

from the operating blocks

OB33

and OB34 have to be unmasked according to the following PCU

configuration:

AUF

"SYS"

Call

SFC 36 (Quittungsfehler ausblenden)

PRGFLT_SET_MASK

:= DBD160

ACCFLT_SET_MASK

:= DBD164

RET_VAL

:=#iRetVal

PRGFLT_MASKED

:= DBD168

ACCFLT_MASKED

:= DBD172

CALL

FC727 (...)

If

an extra ICM call is removed, you will have to use the application

"Parameterization" to switch

back

the ICM to cycle time in seconds:

● Set

hidden attribute "T100MS" = 0.

More

Information in the faceplates

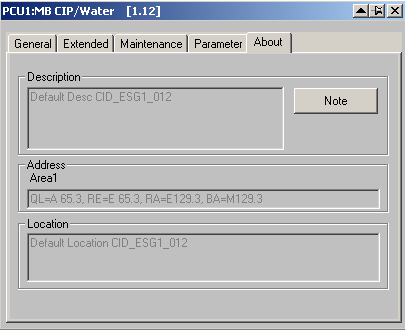

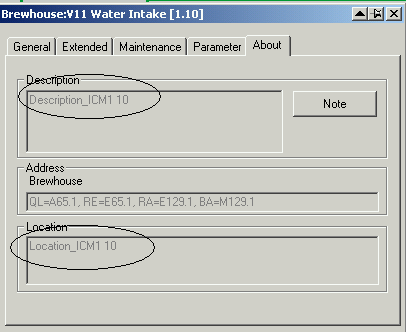

In

the tab "About" configured information is displayed

(Description, address, location).

This can be defined in the

folders \windcs\pcu.00x\ Desc.10 and :\windcs\pcu.00x\Location.10 and

:\windcs\pcu.00x\Address.10

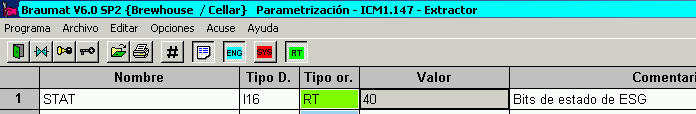

ESG 1+2 for the ICM faceplate

Mess

for the Analogue faceplate

Set

all ICM to Simulation Feedback

Write

AFFE (Hex) to DB701, DW10.

Simulation

with AFFE in DB701 does switch off transfer to the Output DB605.

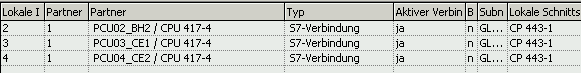

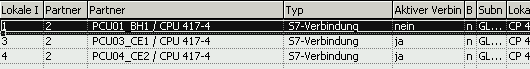

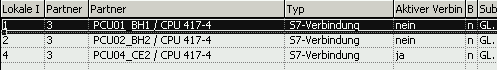

Cross-Communication

with Braumat

Define

in Netpro the Links for PCU1 for example

For

PCU 2

And

for PCU 3

Set

the PCU with the higher number to active.

Download

Netpro to all machines

Now

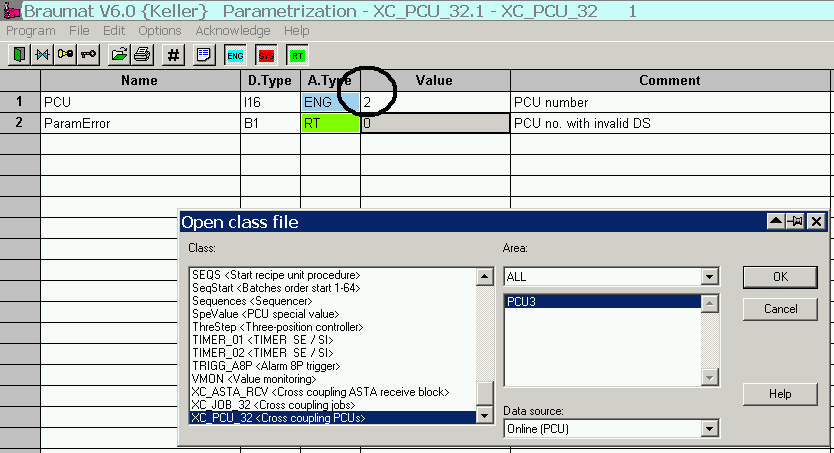

you need to setup the cross-communication in the Parameterization

“XC_PCU_32”

.

Where

as number “2” is the number of the Partner PCU (adapt to

your configuration).

You

need to make this definition in both PCU.

Then

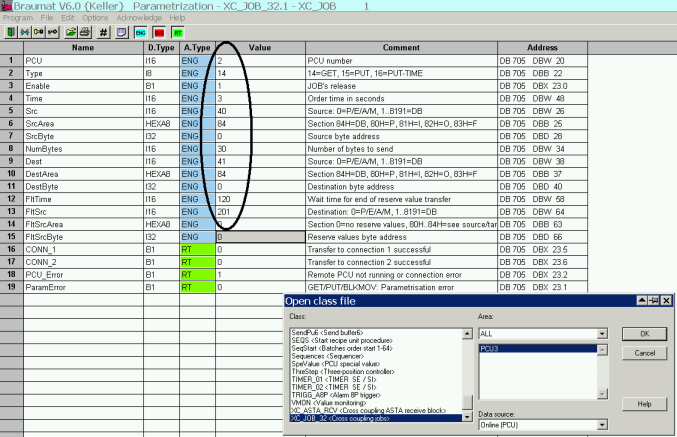

go to XC_JOB_32 and fill the PCU-number, GET or PUT, and all the

other data like in here:

in

this example. Get from PCU 2 DB40, starting from byte “0”

30 bytes to DB41, DW0, all 3 second.

You

need to make this definition only on one PCU.

If

you have problems, restart the S7-CPU

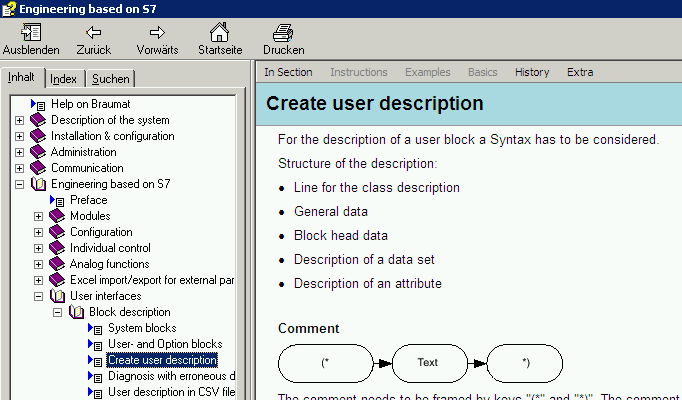

1.4Making a new Structure (new function) in the Parameterization

Look

in c:\windcs\param.pcu\optionen\PARAMUSR.PCU for an example.

Copy

your File name.pcu to the according PCU-Directory. \PCU.00x

To

evaluate set parameter in \sys\om.ini

;Show

OMs tracing dialog at the beginning (1) or don't show om-dialog (0)

bTracingDialog=1

;Tracing

is enabled (only used if bTracingDialog=1) (1) or disabled (0)

bTracingOn=1

and

reset if finished.

In

V7 these objects need this header

object

AIN_ext=DB727;(*Measuring value*)

CID=2001;

max=512;

offset=300;

length=108;

number=DBW8;

filename=mess;

classtype=1;

version=0x08000000;

the

last 2 lines are new!

Here

in the manual you find more information about the feature:

1.5New Message-class with values

For

user-specific messages, a separate alarm-module is available that can

be supplied with additional values.

Input

the Message-Text in MELDUSR.TXT. Call FC713

More

settings in \WINDCS\SYS\MELDCLASS.INI

Search

for FC713 in the manual for more information

1.6Finish Windows-Shell and return to Braumat

Call

\Windcs\sys\EndExpl.exe

1.7Making an automatic Backup of the S7 to Braumat

C:\Windcs\sys\TRANSBST.EXE

/u:upload

in

c:\windcs\TRANS\upload.trs are all files to be backed up

/U:<file

name> Upload with Config file <file name >

/D:<file

name> Download with Config file <file name >

/S Program

execution with hidden window

Example:

D:\Windcs\sys\TRANSBST.EXE /U:S7PCU001.trs

You

can trigger now this command with the Tool prosched.exe and

prosched.ini (look “Starting

Programs Time-Planned”)

1.8Messages on the client

Change

in PCU_serv.ini

[Remote]

;Show

messages of remote PCU-Servers

ShowRemoteMsg=1

1.9Having less Messages in the PCU_Server

Too

many Alarms prevent the Operator from locking to the Messages.

Here

you can filter messages:

In

Parameterization in Dis_MSG (Disable Messages) you can remove the

whole going-messages.

In

Parameterization in PCU_Gen with hidden attributes you have more

switches

1.10Filter Messages of certain PCU on IOS, no Alarm in Client-IOS

In

d:\windcs\sys\PCU_SERV.INI there are switches

;Messages

from this PCUs will not be displayed

NoMsg=5

means

send Messages of PCU 5

;List

of computers that are to receive telegrams of type x

7=IOS11

means

send Messages to Client 11

1.11Synchronize the Time on several PCU by a IOS < V7.0

Use

the function windcs\sys\transtime.exe with the transtime.ini-File and

input all PCU in the ini.file. With that function, you send the Time

from IOS to PCU.

Transtime

is activated by transtime.ini

Note:

Telegram type 7 should be deleted in the FIFOs of the according PCU

and also in Area.ini

It is also not practical to transfer

the time via PCU cross-coupling or to forward telegram 7 to other

IOSs on the IOS level using `pcuserv.ini’.

Starting

‚Transtime.exe’ via the PCU_Server and Scheduler

Contents

of ‚Pcu_serv.ini’:

[Pcu_serv]

;Start

and Check for running of ProcessScheduler "ProSched.exe"

RunProcessScheduler=1

Contents

of ‘ProSched.ini’ - TimeMaster

[Global]

Processes=TransTime

[TransTime]

Application=d:\windcs\sys\Transtime.exe

Type=PERMANENT

ShutDown=0

StartDay=81

StartTime=10:06:19

1.12Synchronisation of time between IOS < V7.0

Start

XNETTIME.exe on each relevant Server and Client. Modify the file

xnettime.ini with according Server. On the Time-server XNETTIME.exe

is not necessary.

Autostart

XNETTIME.exe using the Siteconfig-Tool or with the function

prosched.exe

Or

Use

the function net.exe time \\IOS0x /set/yes to get the time from the

Time-Server, whereas IOS0x is the name of the Time-Server.

In

all ‚Time – Slave' IOSs, the time and date are read

cyclically from a ‚Time – Master’ IOS via the

‚Net-Time’ protocol.

This

takes place with the Batch-File ‚Time.bat’, which is

called from BRAUMAT Scheduler ‚ProSched.exe’ in a

predefined time cycle:

Contents

of ‘Time.bat’:

@Echo

off

Net.exe

time \\<PCNameTimeMaster> /SET /YES

<PCNameTimeMaster>

should be replaced with the computer name of the ‚Time –

Master’ IOS.

The

associated call in ‘ProSched.ini’ for this is:

[Global]

Processes=Time,…

[Time]

Application=d:\windcs\sys\Time.bat

Type=HOURLY

ReqTime=00:10

;to be started each hour at xx:10

In

this case, 'Time.bat' is called hourly from 'ProSched.exe', at 10

minutes past every hour.

1.13The IOS01 computer clock is jumping about x minutes.

The

time in the PLC is different from the time in the IOS. You can

download the time by User-manager, Date Time.

Or

you remove the Time-synchro 7 in the Fifo in the Paramerization

“Fifo”, Global Value.

Time-Synchronization in Version >

V7.0

Select the App

“BM-Config”,

Braumat Basic configuration

Select “change system

time” to allow Braumat to change the System time!

Go to the

App Siteconfig

Select

on (Time)-Server (IOS01) and set this as "Time master" (it

will send Time to the PCU)

Select at all other

Server (also in other Area): Retrieve system time from Time

master

Select at all Clients:

Retrieve system time from Time master

Select at all PCU: Retrieve

system time from Time

master

Remove Telegram 7 in the

Fifo!

Link the other Areas by

Multi-Client-Functionality.

In order to have

Time-synchronization, you have to login as Braumat and not as

Administrator that it works.

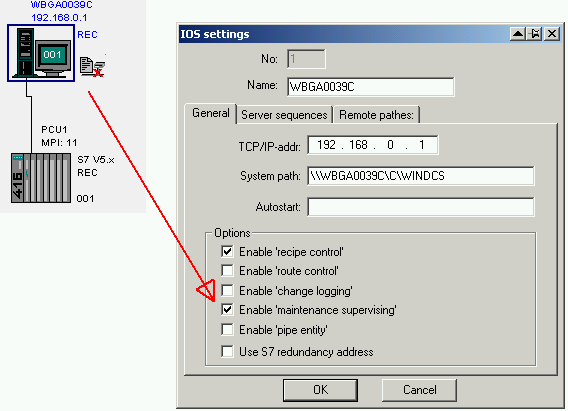

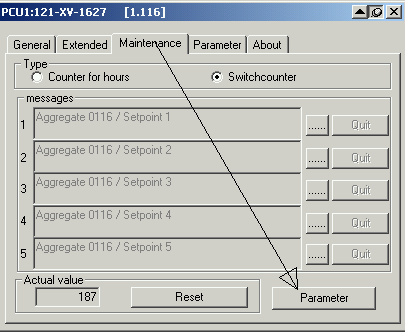

If

you want to use the Maintenance-Information (hrs-Counter,

switch-counter) and get an Alarm

Activate in the Configuration

Then

define a time in mainssupv.ini

There

are Alarm-Messages generated and additional files only with the

Maintenance-Alarms are stored in

.../Windcs/pcu.xxx/MAINT/maint_YYYY_MM/maint_YYYY_MM_DD.TXT

Very

useful for to verify what Unit needs maintenance!

1.14Installation on Windows 7

If

you install Braumat on Windows 7, you have to switch off UAC,

otherwise you will have problems.

How?

Make a command-line (Start, execute) and input UAC. Then switch it

off by putting the slider completely down. Then install Braumat.

More

on here:

http://windows.microsoft.com/en-US/windows7/Turn-User-Account-Control-on-or-off

Ok,

if you have Ultimate Edition or Enterprise Edition of Windows 7

you can install Vietnamese language and get Braumat run in that

language as well (see attachment how it looks), supposed your first

Windows 7 was English.

Free

download of language-packs under

http://windows.microsoft.com/en-US/windows/downloads/languages-xp

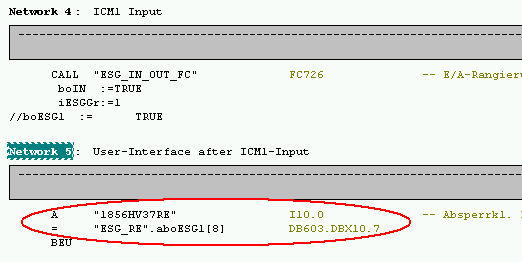

1.15How do I map different ICM assignment (inputs / outputs)?

Sometimes

it is necessary to deviate from the standard addressing (ICM 1.1 = I

64.0 E / Q 64.0). You have to do this

Different

inputs:

Open

the SIMATIC Manager, FC700, and change it as follows:

Map

at the marked point the input to the corresponding data in DB603.

The

original input can then be used elsewhere.

For

other ICM groups go to corresponding network 9, 13, 17

Do

not remove the BEU!

Different

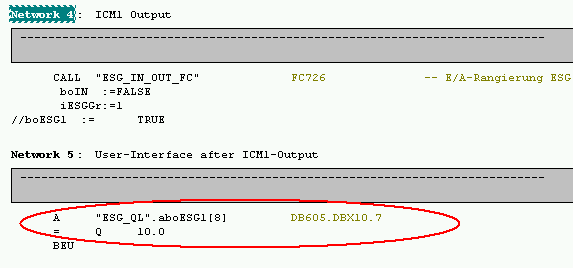

outputs:

Open

the SIMATIC Manager, FC701, and change it as follows:

Map

at the marked point on the Output to the corresponding data in DB605.

The

original output can then NOT be used otherwise.

For

other ICM groups go to corresponding network 9, 13, 17

Do

not remove the BEU!

Version

7: This mapping can be done now direct in the Paramerization of ICM,

AVA, AOUT and TIMER.

1.16Start a process-picture or a application: userstart.exe

The

application userstart.exe allows you to start a

process-picture or any application with any IOS command

like changing a data word

Modify

the ‘USERSTART.INI’ Datei:

[IOS1]

;Data-Source

is PCU 1, DB709 DW 2.

DataSource

= 1,0,709,2

;StartApplication:

here you define the application in your case the Media Player

StartApplication

= C:\Program Files\Windows Media Player\wmplayer.exe

;StartList:

here you have the video-file in a text-file in the folder \windcs\sys

StartList

= files.txt

;termination-Button

beenden

= 1

;0

= no Alarm, 1 = MsgBox

ErrorHandling

= 1

;if

the pointer is wrong in DW2, take line 1 of text-file

Default

= 1

To

activate that function you can use prosched.ini-file

By

starting a window is opening with the corresponding data and

application.

1.17Engineering languages

The

engineering languages can be defined with the ‘SiteCfg’

Tool in the menu Area-plant settings. The plant texts are located in

‘…\windcs\PCU.nnn\texte\... for different languages.

Further information is given in the manual ‘02_Inst-Config.pdf’,

in subsections ‘Modifying factory settings’ as well as

‘PC definitions’.

1.18Different location for archive - data

BRAUMAT

provides optional directories for different types of data.

The

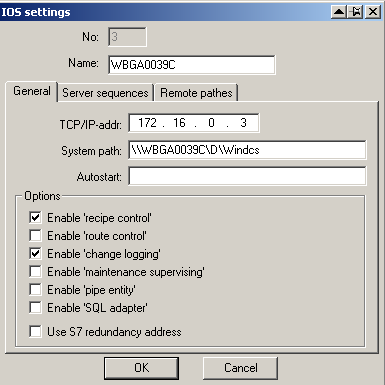

remote path settings are managed in the “Configuration"

program.

If

you would like to change the default path “c:\windcs”

you can enter your

new path

via “Configuration” dialogue

Braumat

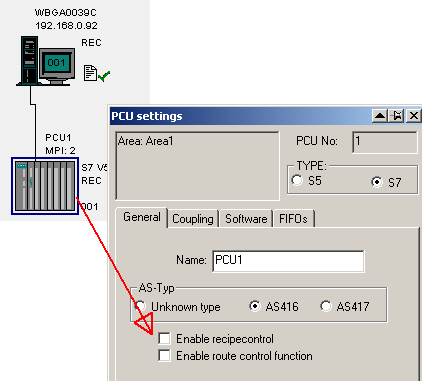

is not starting as a Recipe-Server, because one PCU is not present

You

can switch of recipe-Server-Function for the PCU not present in the

function Administration, Configuration:

Restart

Braumat and it should work.

You

can integrate a S7-400 to Braumat without the need to have any

Braumat-Software in the PLC

You

can visualize all values in the Graphics and change them.

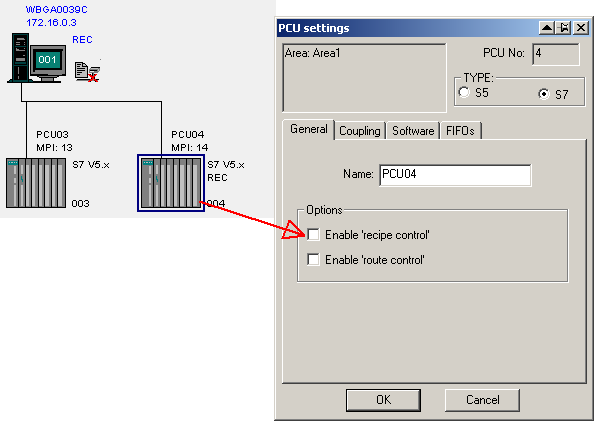

Integrate

a new S7-416 with the Function Administration, Configuration like

this:

Then

open the file \windcs\sys\area.ini and write “Sistar=0 “to

the PCU S7_400

[PCU04]

Name=PCU04

EnableRecipeControl=0

Family=S7

IP_Addr=192.168.0.2

l2_addr=2

Sistar=0

SW_Recipe=V5

Communication

can be by Ethernet or MPI!

1.19How to make Braumat more save against Virus-Attacks

In

the Standard-Installation Braumat is not very save against

Virus-Attacks, because it is running with full Administrator-rights.

How

to change this?

You need SIMATIC Net as driver instead of

Soft-CP (is shipped with Simatic-Manager).

Remove the

Share from the complete drive and put a share only on \windcs and

\Temp and \Tmp.

Then

make a new User only with User-rights (not Administrator-rights).

Restart

with new User.

Version

7: Above mentioned

precautions are the standard in Braumat 7 now

1.20Minimum Safety-Interlocks

In

the FB1226…FB1233 (ICM-group 1,2..).

Minimum

is:

Inlet-Valve

of Tank closed if Tank is full

Pumps

must have open valve at the Inlet. If the valve is the outlet of the

Tank, check Low-Level sensor as well.

No

Steam-Heat-Exchanger on, if the Pump is not running.

Interlock

of Production and CIP (interlock the sequence with

Sequence-running-flag )

ON

M 657.7 SEQU016_ATS //CIP running for MTK

O

M 656.0 SEQU001_ATS //MTK is running allready

=

M 640.0 SEQU001_DB //MTK

More:

Switch

Valves delayed of if there is a pump for to avoid Pipe-noise.

CIP:

Switch next Step with conductivity delayed because it falls sometimes

and raises again.

CIP

Pre-Run: Take Fresh water if Staple-Water Tank is empty

CIP

Return: Go to Drain if the Tanks are full

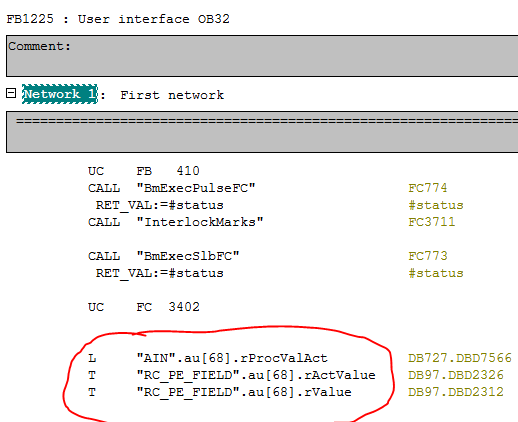

1.21Analog Measurement-Values by ASI-Bus or other Profibus-Source

The

values can be transferred manually in FC700 End of Netzwork 21. to

DigitalVALPEW or DigitalVal.

1.22Braumat and Real (Version < 7.0)

Braumat

uses in most cases Integer, and you define the comma for the Output

(in the Graphics and recipe).

However

you can show Real in the Graphics with the function Val and then you

select real.

If

you get a Real-value from the Profibus PA for example, you can

transfer this value in this way to the Analogue Input:

//

AI xy from Profibus PA in Real

//

---------------------------------------------------------------------------

L

PID 512 // value from Hardware

L

1.000000e+001 //multiply with 10 to get one comma

*R

RND

T

"MESS".au[1].iDigValue // converted value

1.23Version 7: Much more REAL is possible in Version 7 in the

Parameterization

How

to make a backup of Braumat

Use

the Software “Totalcmd“ (www.ghisler.com)

it is more easy than with the Windows Explorer.

Make

a new folder Windcs_4_5_13 whereas the extension can be the date.

Mark

all (Ctrl + A) of \Windcs or the name of your project and Copy all

(F5) or copy, paste to the new folder.

You

will not have a problem, although the System is running.

If

you do not need the Archive-Data refrain from \FRPROT, \meld,

\SRPROT, \Trend, and \Logging and the file will be less big.

1.24Using the Backup Windcs instead of the running system

Start

c:\windcs\sys\Terminator.exe

Rename

the windcs-folder new to old and backup to Windcs.

Start

again

If

it does not work, restart the computer without Braumat as shell. Look

in the documentary how to remove the shell or use the tool “Autolog”

from www.braumat.de.

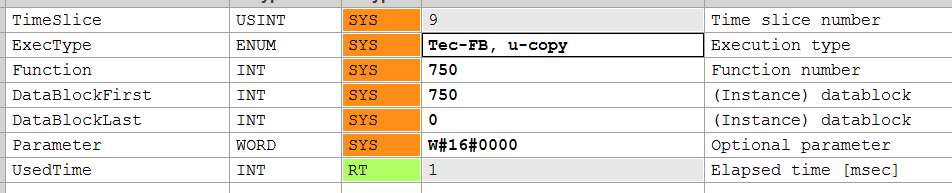

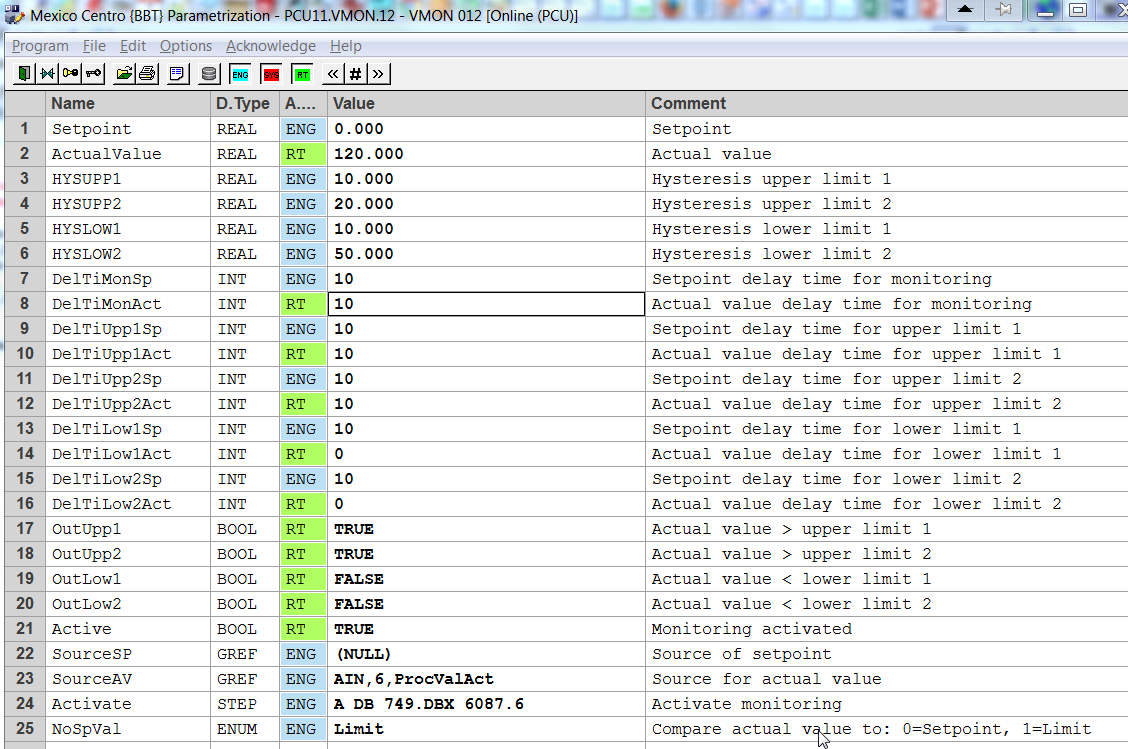

1.25More Analog-Switches delayed using the Modul VMON

VMON-Function

gives you 4 more analogue-switches each can be delayed, a very useful

tool. And you can compare 2 values.

The block is disabled by

default. The block VMON (FB750) should be called from the scheduler.

The activation may be done in class “Schedule <Schedule

List>” in data record 54 or 60 set to enable. And Input

Function 750 and DB750 and Tec-FB, u-copy.

2How to improve the Performance of engineering

Engineering-costs

is a very sensitive issue. May be some of these hints help to improve

the speed of engineering.

Change

files directly

Braumat

is based on many text-files and Dbase-Files, which can be edited

manually very easy.

BUT

open this file

afterwards in Braumat-Textparameterization and save to have the right

format and for to synchronize on the other Server.

Change

of dBase-Files

For

the Dbase-Files you can use Excel, or the Total-Commander-plugin

“dbaseview.zip” (Freeware, also change the file with

that).

If

you change with Excel

(possible) take care not to change the column-width (you destroy the

file). And to extend, only insert new lines but not append!

Which

files are used for what?

For

recipe-Editing a lot of files are in \WINDCS\PCU.00x\recipe\. Or you

change something in the recipe or another application, and check with

Total-Commander “search file”, extended, not older than 1

minute…;

Also

the Text-Files in \WINDCS\PCU.00x\texte can be edited externally, but

to get them to the right format open them in Braumat and just save

them. In this case the Format will be checked.

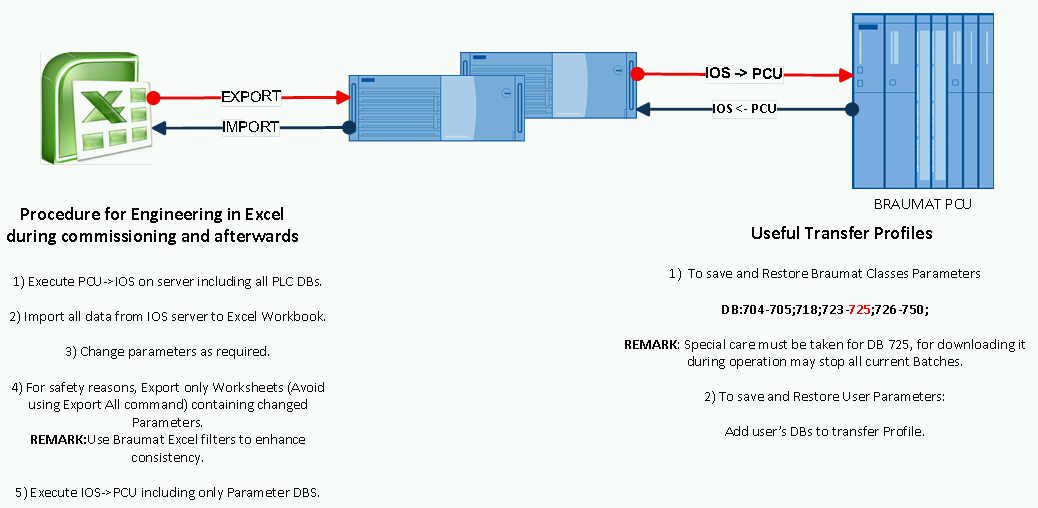

Braumat-Excel-Database

and Productivity-Tool

Using

the Braumat-Excel-Database from \WINDCS\EXCEL\ helps a lot to speed

up engineering and to work with several programmers at the same time.

But you need first to upload (if you have new Blocks in the PLC

already) the DB-Blocks from the PLC by the Application in

Administration, File-Transfer, PCU->IOS, DB709-750.

Then

you Start \WINDCS\EXCEL\macro.xls. Leave it open in the backround

Start

Start \WINDCS\EXCEL\Param_PCU00x.xls

Import

Data from Braumat by

pressing Alt + F8 or Extras, Macro, Macros. Import one Table.

Now

you can do your complete planning of the Plant (in the Folder

Sequences) and all Braumat Modules are available. Also for

recipe-system it is very useful and speeds up time a lot (Tab

epe.ini, epar.ini, sequence.ini). But take care if you Export it is

overwriting Recipe-parameters! So to be sure Import first to Excel.

Also

the Special-values (SpeValue) can be Setup here. I recommend to

Preset all values to “sec” and “KT” and

“2005” (5 sec) first.

Export

Data to Braumat by

pressing Alt + F8 or Extras, Macro, Macros. Export one Table.

Then

you need to download the Data to the PLC by the Application in

Administration, File-Transfer, IOS->PCU, DB709-750.

If

several programmers are working on a project, it helps also to

synchronize the Data if each Sequence has its own DB for necessary

fags.

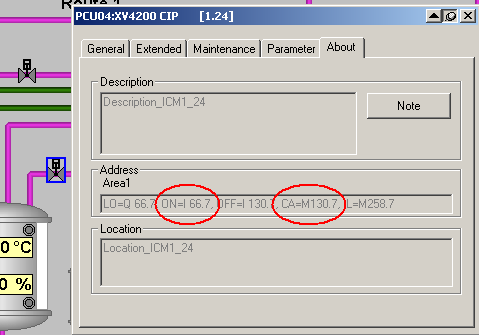

How

to find the corresponding Flags for an ICM in the Screen?

You

have a easy access to all Braumat-Addresses of Input and ICM in here:

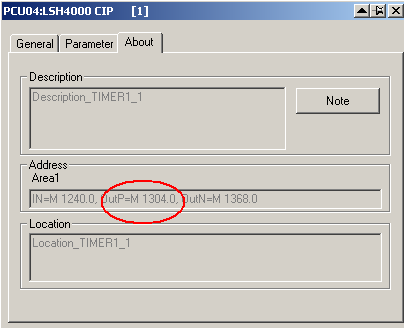

The

same in the Timer-Faceplate:

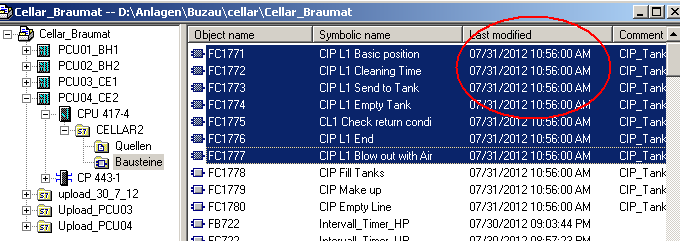

Simatic-Manager

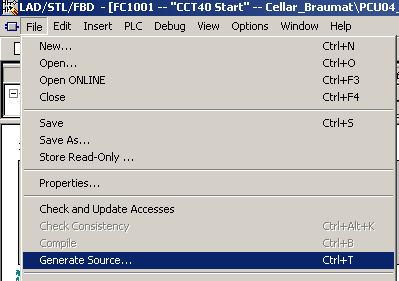

Sort

the files in Simatic-Manager by “Last modified” and you

always have the last changed Block on top. But you need to remove

some column with “options, customize, columns” first.

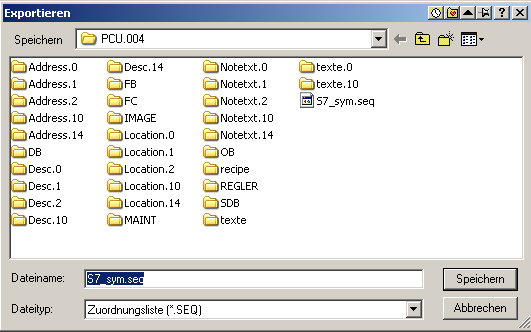

Export

Symbolic-List to a Textfile

You

can export the Symbolic-list (Simatic-Manager, Symbol-Table, Export

to *.seq-file), change (by Excel or Notepad++) and Import. But before

that you have to delete the complete Symbolic-File first (so make a

backup of the project first). And Import by Simatic-Manager,

Symbol-Table, Import). How many errors? Take care, also the warnings

will have effect so it should be 0 Error, 0 warnings!

Ok,

with Excel it is a bit different. Excel will remove the first column

if there is nothing. So write anything in the first column (new line

and put a x) before saving. You can remove the first line after that

with Notepad and Import to Simatic-Manager. Works fine!

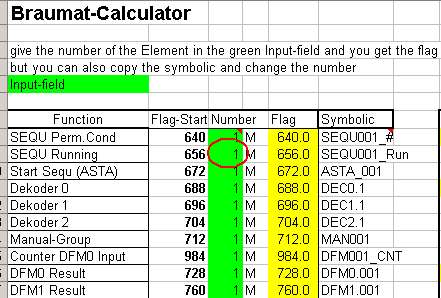

Braumat-Calculator

The

Braumat-Calculator (can get from me) helps also to find the according

address and DW very fast. Just Input the number of Sequence or DFM

and you get the according address.

More

Tools

Notepad++

is a amazing Freeware

where you have a lot of Tools to make Braumat-life more easy.

For

example “replace in Files” to replace a symbol in all

pictures

Or

the column-Mode to extract or change only some columns of the file

(Recipe-files like sequence.ini, epe.ini etc)

Or

you can records keystrokes and let them run many times and much more.

You

can easy copy Step7-Code to Notepad++ and change and copy back.

I

keep the Symbolic-List (located in \Windcs\PCU00x\s7_sym.seq allways

open in Notepad++ to find fast (Ctrl + F) the according Symbol /

Adres. Export from time to the Symbolic-List of the Simatic-Manager

to Braumat

You

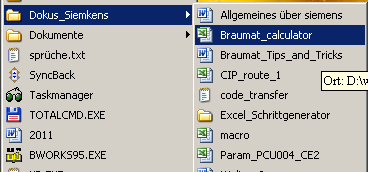

can make a Desktop-Folder

with all the files (link) relevant for the project (xls…) and

shift them to the Start-Menu for fast access. Also “Last

Documents” of Windows (Start, Documents…) helps a lot.

If

more than one

programmer works on a

S7-Project, use DB.DBX for flags instead of the assignment-list for

better synchronisation. For example each Unit has it’s own DB.

Then you are free to synchronize easy.

Program

interlocks (full

vessel / empty vessel close according valve, pump on only if valves

are open etc) not in the program but in the Interlock FBs 1226-1233.

It saves code and makes the programming more transparent.

If

you have a new project but use the Software of another project

You

can speed up the engineering by generation the User-Blocks of the old

Project to Source in Symbolic (generate Source in Simatic-Manager,

but in Symbolic). Then change only the address in the Symbolic-table

to the new address and translate. Wow! All with the new addresses

now. After that you can also modify the symbolic in the list etc.

Good luck!

Export

Symbolic-List to Braumat

You

need to export the Symbolic-List if there have been many changes to

Braumat. You can

export the Symbolic-list (Simatic-Manager, Symbol-Table, Export to

*.seq-file) and save it to windcs\PCU00x\ with Name “s7_sym.seq”.

If

you have a language-depending engineering, you also need to export to

windcs\PCU00x\Texte.x

Synchronize

Symbolic-List with Braumat

You

have a very good Tool called S7-Symbols sync in Braumat to realize

this. You select the Modul you want to synchronize (ICM etc) and the

you see the differences. This works with the exported Symbolic-List

in windcs\PCU00x\ or windcs\PCU00x\Texte.x

2.1Replace Hard-Disk of PC

Backup:

Use Acronis-Boot-CD and a USB-Harddisk: Backup all Partitions you

need from the other Server.

Restore:

Use Acronis-Boot-CD and the USB-Harddisk: Restore all Partitions you

need.

Start

NewSID (Freeware from SYSINTERNALS) and change IP-Adress of the

Network

2.2Delay off-Signal of Timer

You

have a switch-off-Delay if you Invert the negative Output and check

for the negative Impulse.

2.3Full & Empty-Signals

Normally

Empty-Signal = 1 if sensor is covered, that means “0” if

empty

Normally

Full-Signal = 0 if sensor is covered, that means “0” if

full

2.4How to deactivate cross-communication?

Go

to XC_PCU_32 in the Parameters and remove the according PCU-number.

2.5How to get more Instances of a Class (e.g. PID etc.)?

If

you open Parametrization you have the number of ICM on global Data.

Here

you can extend the number of ICM, same for analogue etc.

Then

take a look in the manual for the according addresses or take my

Braumat-calculator

2.6Analogue-Values in Real

You

can get the Analogue-Values in Real by Loading "MESS".au[1].rXist

Also

the AFIX provides Real

Display

Real on Screen with the function VAL (Integer or real value)

Version

7: much more real is available.

2.7If a sequence should always run program like this

in

the according FB 100x (Network 2 or 3)

//start

Sequ if not started restart

AN

"SEQU_Run"

FP

M 30.0 //use one flag for impulse

SPBN

a001

R

"SEQ".u.STATUS.boMan

L

1

T

"SEQ".u.iNewStep

L

1 //check this in the Parameters!

T

"SEQ".u.byRecType

L

1 //check this in the Parameters!

T

"SEQ".u.iRecipe

L

37

T

"SEQ".u.iBatch

L

1234

T

"SEQ".u.iOrder

a001:

NOP 0

or

you use the SEQS (Sequence-Start) Type 4

AN

"SEQU_Run"

S

"ASTA_013"

A

"SEQU_Run"

R

"ASTA_013"

2.8Trends on Client

To

see trends on client modify the file \Windcs\sys\trendman.ini

Server=1$\\IOS01\D\Windcs

Whereas

IOS01 is the Server with the according curves

And

modify Client_noWrite=1

2.9Trending call in the process-Image

It

is possible to call the Trend-function from the process-picture by a

button. Most easy it can be done with week-curves, which is nice

because you do not need to select Batch and Order-Nr.

You

can make a week-trending picture and access the Batch-Trending Tags

as well. So you do not need to make extra definitions for a

week-archive.

This

is the function in Image Design using the function “PC-program

Start”

Kurven.exe p MTK1.ltb $BYEAS 0 $BORNS $BBANS

'MTK1-Trends'

or

like this: Kurven.exe c BH1 LT.ltw - -,0

For the symbol use a

Bitvariable linked to any flag for example this symbol: KURV_SYM.BMP

2.10A ICM generates an Alarm, because the Feedback is going away for

a short time (Seat flushing).

You

can avoid this if you Input in the Paramerization a time-value 0-15

sec at Error-Time in the Dataset. If you Input 4 you see 44, but

that’s because the second “4” is the actual value.

If

you want to know the Step-Number and Basic Operation number in the

GOP

Make

like this

T

#iStep //Step-No. of the sequence

TAK

T

#iBOP //Basic Operation number

Display

of “more Info” in the ICM-Faceplate

Y ou

can copy and paste the Symbolic of Step 7 for ICM to the Excel-Sheet

in \Windcs\Excel\ and Export. Take Folder ICM and column “Location”

and Description

ou

can copy and paste the Symbolic of Step 7 for ICM to the Excel-Sheet

in \Windcs\Excel\ and Export. Take Folder ICM and column “Location”

and Description

Max

number of windows

Can

be setup and should in the file \windcs\sys\sys.ini

;Maximum

account of SISTAR-Windows or 0, when there should be no limit

WndMax=8.

for example 8

Multi-Client-selection

windows is not popping up prior to start a applikation

Press

CTRL-key + application to get it back.

There

is a Message-window coming when I open a ICM-Faceplate

The

Error may occur due to the Maintenance-Database. How to solve it? Go

to the highest number of ICM in the Screen (or define one ICM 4.255

etc) and open that go to Maintenance, select Parameter and close.

And

then press “ok”. Better now?

2.11Read-only-PCU, no write to PCU

Change

in \Windcs\sys\Sys.ini in the according IOS

[Trans_NT]

;List

of "read only" PCUs

NoWrite=1,2

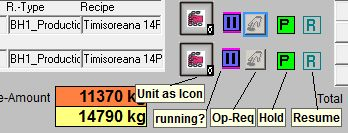

2.12Hold and Release in the process-Image

For

to display flashing Hold in the screen (may be next to

Sequence-Faceplate) select Flag R_Held of the Unit-Faceplate

For

to release from Hold show with another Button R_Restart-Flag of the

Unit. May be with Operator-Level “-1” to avoid a window

popping up.

For

to show whether there is a Stop of the Sequence show flag R_Running

of the Unit flashing

To

advise the Operator about necessary action, you can make another

symbol with flashing Operator-Request linked to Flag OpReq of the

Unit.

A separate Button for to show the Icon of the

Unit-Faceplate is very useful

In

the Software outside the Unit check for AN

"SEQ".au[x].CTRL.boHeld for the Held-Signal.

2.13Synchronization of 2 IOS takes too long

You

can modify the file d:\WINDCS\ETC\SYNCHRO.DEF to speed up

synchronization

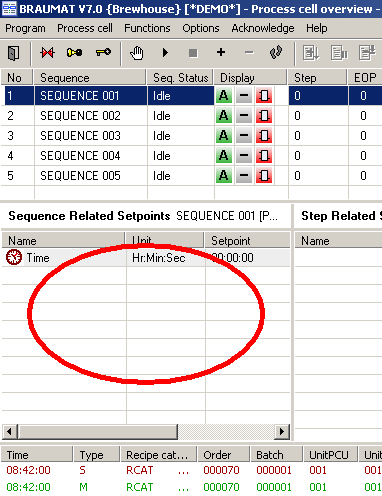

Setpoints

at the left side of the Sequences overview window

are

defined in Recipe, Project-Planning, Equipment-data,

Device-Hierarchy, Unit, open the “+” and then right

click. Here you can define what you want to see on the left side or

when the sequence is in Stop. Could be all Unit-related DFM.

2.14Changing the size of the Picture

The

size of the picture can be modified by the Tool “Image

Design-Sizer”.

Image

Design-Sizer is

integrated in the system. To

activate change in \windcs\sys\Image Design.ini [Options]

Image

DesignSizer = 1

Then

there is the feature is available in picture-construction, Tools

2.15Standard-Configuration for the Fifos

With

this Configuration, the Standards are activated:

Fifo

1 + 4 (=Server 1+2): 3+7

Fifo

2 + 5: In here System puts telegrams according to Recipe-Server,

don’t change!

Fifo

3 + 6 (=Server 1+2): 5+6+14+18

Configure

the Fifos for several configurations

You

can use the File fifoconf.exe to do that.

2.16Copy Graphics to all relevant IOS

Switch

in \Windcs\sys\biko.ini

;Copy

files to all GP_PROJ paths after saving files

CopyFilesToAll=1

2.17If a Output(ICM) is not activated

Set

line 1 in ICM-Parameters to “0“. Sometimes it helps

2.18Add a new class in the Excel-Engineering-Sheet

If

you want to add a new class in the Excel-Engineering-Sheet

(Param_PCU001_1.xls) you can implement them very easy by yourself

(Braumat is a open system!).

Simply

make a new sheet, name it “Poly” or other name of the

Instance.

Copy

an existing content from another Instance.

Modify

the symbolic, names and presetting according the

Parameterization of the instance.

Names

must be correct, so maybe you copy from ParamS7.010 (or your

language-file).

Finished!

Already

you can import / export.

If you want to have it included in

“Import all, Export all”, then open

\Windcs\Excel\macro.xls; Macro, Modify.

Then extend the new

function to the list you see with the same parameters ,2 ,0).

If

you switch on the \sys\tracesvr.exe you will get Messages if there

are errors.

2.19How to integrate a new OCX in Braumat Image-Design

You

generate the Code by VB or Visual C or whatever.

Copy

the according GUID for this in \windcs\sys\ocx\sisctrls.ini

Like

that: Guilherme_special

;{D33A5C15-13FD-11D7-97E9-000476135A6D}

This

number is generated from Visual Studio and might be seen with the

according name in the registry Class_ID; That means you register it

and look in the registry for the according GUID. Or google for OCX

GUID

Then

you register the ocx with a batch like that:

regsvr32

/s Guilherme_special.ocx

Then

you integrate this OCX in Braumat with Image Design, Controls, add

any one, press button “others” and select your OCX.

For

communication to the PLC datalink.ocx is very useful, but not

supported any more although it is working fine.

2.20TCP/IP-connection between IOS is unstable

IP-Masks are

ok (255.255.255.0) and unique?

Is there a

Domain-Server? Does he work properly?

Are Firewalls

switched off?

The host-Table

(in c:\WINDOWS\system32\drivers\etc\hosts) can help in heterogeneous

networks to speed-up build of communication. BUT the file has to be

unique in the complete plant! Otherwise you will get strange

problems!

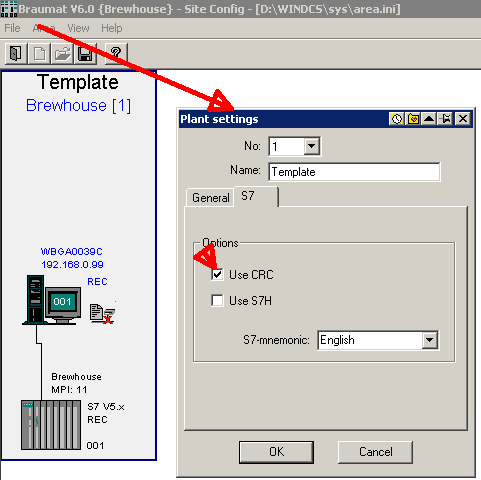

2.21Braumat with a PCU-H (417-4HT14-0AB0)

You have to

set the USE-CRC-flag in the Site-config if you are using just 1 PCU

If you have 2

redundant CPU you have to assign “Use S7H“ as well.

2.22Switching between Braumat V5.x or V6.0 and V7

In the

System-Path of windows (System-settings, System, extended settings,

extended, Enviroment-Variable, Path) D:\windcs\sys has to be at the

beginning.

To activate

Braumat V6.0

Prior to start

Braumat V6.0 Start x:\Windcs\SYS\ocx\register.bat and start Braumat

V6.0

To activate

Braumat V7.0

Start

x:\Windcs\SYS\ocx\unreg.bat from Braumat V6.0

Rename \Windcs

to \_Windcs for example

Then Start

\Program Files\Siemens\Braumat\sys\register.bat and start Braumat

V7.0

And vice versa

to go to Braumat V6.x

New! For

Autostart of Braumat you have to Input in the Registry only

newmenu.exe without Windcs\sys!

2.23Register OCX with Admin-Rights

For to

register OCX in Windows 7 call Total-commander in Admin-Mode

(Properties, Compatibility, Admin)

2.24Disable manual switch to the next Step for critical technical

configurations (V7.0)

In

case some steps are very critical (pressure cooking), manual change

of the Step could have disastrous consequences you can lock the

manual change of the Step with this switch.

Set

"SEQ".u.CTRL.xSuppressOpStepChange to “1”

No

manual change of the step is possible.

2.25Transfer Real to Analog Input

L

Real-value from Profibus

L

1.000000e+001

*R

RND

T

"MESS".au[1].iDigValue

2.26Resize pictures .bik

Here

(above) you find also the Tool to resize pictures .bik “process

diagram conversion”

But

the background-picture *.bmp has to be resized manual.

2.27Material-Sequences

In

the recipe you have the function Material-Sequences. It is possible

to define only the successor. The predecessor is coming automatic

depending from the definition of the successor (f.e. after water all

material is possible)

2.28More hints for V7.0

You

have a Braumat-User-Account; Login with this name

When

login as Administrator no “synchro time” is possible.

Only when login as User

A

old Project can be converted to V7.0; the dll’s are deleted,

the Text is extended to 32 sign, recipe is adapted etc.

Windows

UAC can be on level 3.

1,7

MB of memory is now necessary, more than the CPU 414 can manage. The

BRL-Objects need a lot of memory!

Cross-communication

old-PCU and new is working.

In

the application siteconfig input the correct Software of the AS. It

can be a Version 4.6!

Enginnering-Lizens

is linked to one PC.

For

each PCU you need a Lizens-key on each Server

In

PCU-serv.ini you can adjust that 32 characters should be visible.

With

Unit -OCX you can also generate very individualistic Faceplate for

the Unit.

Lean

1 PCU, 1 Server 50% more cheap; A Client is possible

Changing

the Main-Menu can be done in \Program

Files\Siemens\Braumat\Texte.1\BM_AppCenter.ini

2.29Line-Recipe is very useful in the Tank-farm, if you have similar

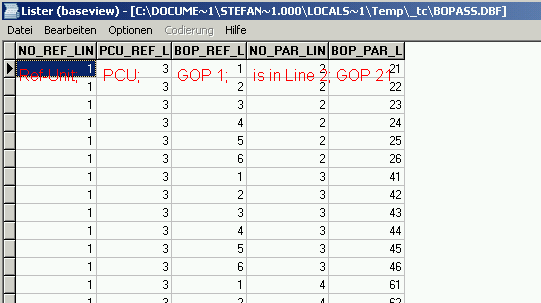

Tanks.

For

that you have to modify the file

windcs\recipe\project\BOPASS.DBF

In

this case Unit 1 GOP 1 corresponds to Unit 2 GOP 21

In

this case Unit 1 GOP 2 corresponds to Unit 2 GOP 22

In

this case Unit 1 GOP 1 corresponds to Unit 3 GOP 41

And

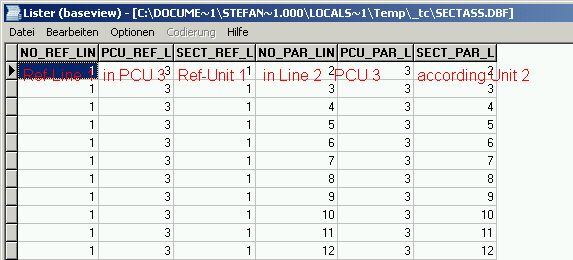

the file windcs\recipe\project\SECTASS.DBF

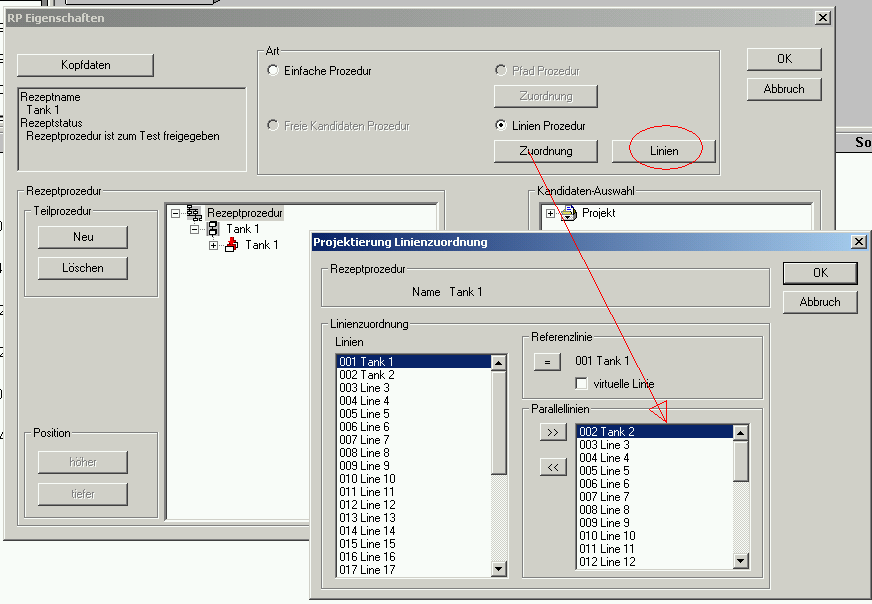

Then

you make for all relevant EOPs the DFM-Definition in the recipe

Then

you first Input the name of the Lines (Tank 1, 2…)

Then

you define a Reference-Line (Tank 1) and all the parallel Lines

You

Input only Recipe Tank 1.

When

saving all the other recipes are generated.

Good

luck!

3Triggering of “User step protocol” entries FC 771

To

enable a detailed evaluation of the recipe setpoints/actual values in

the step log tables of a connected SQL database at a later time, for

example, additional step telegrams can be triggered by calling the

new

FC

771 "BmTriggerUsrStepLogFC"

in

the EOP FCs or UNIT FBs at any time.

Cross-communication

If

it is not working restart PCU’s on both sides.

Here

one example for the configuration of Braumat of S7-connections

PCU

5

to

PCU 6: local ID 6; Partner ID 5; passive

PCU

6

to

PCU 5: local ID 5; Partner ID 6; active

Synchronize

process-images on all servers

Referees

to the file \Windcs\ETC\SYNCHRO.DEF and se in \sys\biko.ini

CopyFilesToAll=1

Start

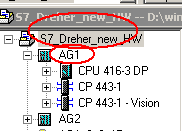

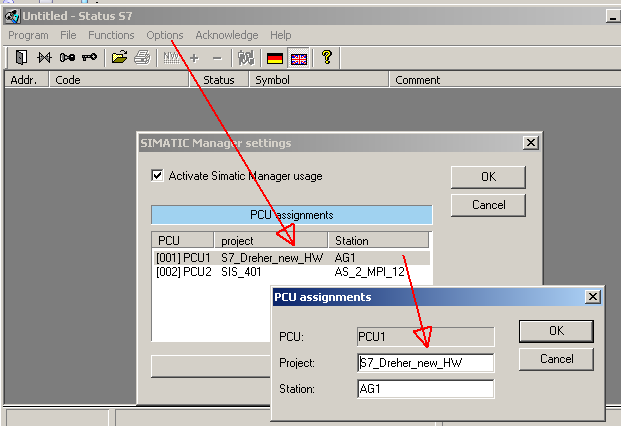

the Step7-Simatic-Manager in Braumat for Transition-Diagnostics etc.

And

write it in the Application Status here for all PCU

Change

in status.ini

[S7]

;Using

the KOP,FUP, AWL Editor of STEP7 for status diagnostic

UseStep7App=1

EnableStep7App=1

Keep

in mind that the client could change the code!

I

big blocks like FB1226 are monitored for Status, it takes a while

until they are opened.

Call

Step-7-Status Programm in picture

Specify

Programm-call in process-image with Status_S7.exe 3 FC153 1 (PCU,

Block Network).

Delay

Step-Time

In

the sequence a delay-step-Time can be defined in Unit-Parameter

Delay_SP (Param-Nr. 81); This is start at every now step and the

result is flag M 101.1 TVERZ.

Display

of the missing condition for the Transition or Interlock by color

In

order to have to Display of the missing condition for the Transition

or Interlock by color you have to set in status.ini

[Settings]

;Change

Color for Negativ-Status

SetColorText_Neg=1

Here

you can see the Transition with color, very useful!

And you can

call the graphical recipe as well.

Programming

Horn

O

M 99.4 //Alarm sequ

O

M 99.5 //Alarm ICM

O

M 99.7 //Alarm Mess

AN

M 134.7 //Alarm Horn

S

M 134.7 //Alarm Horn

R

M 99.4

R

M 99.5

R

M 99.7

//;

A

M 134.7 //Alarm Horn

L

S5t#20s //Reset after a time

SD

T 99 //Time Horn off Auto

A

T 99 //Time Horn off Auto

R

M 134.7 //Alarm Horn

//;

A

M 107.3 //Summary horn flag acknowledge

R

M 134.7 //Alarm Horn

A

M 107.2 //Summary ICM alarm acknowledge

S

M 107.1 //Summary alarm-flag ICM, AIN, ALARM, SEQU

Call

Exec-FB or FC from Screen

in

the Accumulator 1 the Interface-value is transferred for evaluation

A

setpoint in the recipe editor can be write-protected

by

adjusting '-e' in the recipe editor.

Example: 2.123-e,3.12

Reset

the Alarms at the beginning of a Unit

A

M 102.2

R

DB725.DBX 101.4 //"SEQ".u.STATUS.boMsgError

R

DB725.DBX 103.5 //"SEQ".u.STATUS.boMsgSystem

R

DB725.DBX 103.6 //"SEQ".u.STATUS.boMsgWarning

R

DB725.DBX 103.7 //"SEQ".u.STATUS.boMsgOperating

Braumat-Shortcuts

If

ICM is in manual you can switch on/off directly without the window

by click on the object and press “CTRL” at the same time

You

can open the Image-design directly from the Process-Image by “CTRL”

+ Doppelclick on the picture.

You

can open the Image-design Text-file from the Image-design by “CTRL”

+ Tab-key Doppelclick on the picture. But you have to close the

picture first in order to change it.

No

checkbox “change picture” at Smart Unit

Open

\sys\controls.ini

[SmartUnit]

;Disable

MessageBox on picture change

AskForPictureChange=0

Security-Topics

Braumat

can run as Guest without Administrator-rights.

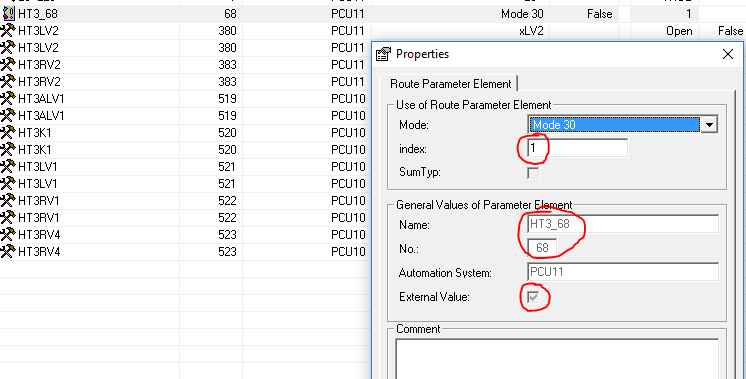

Route

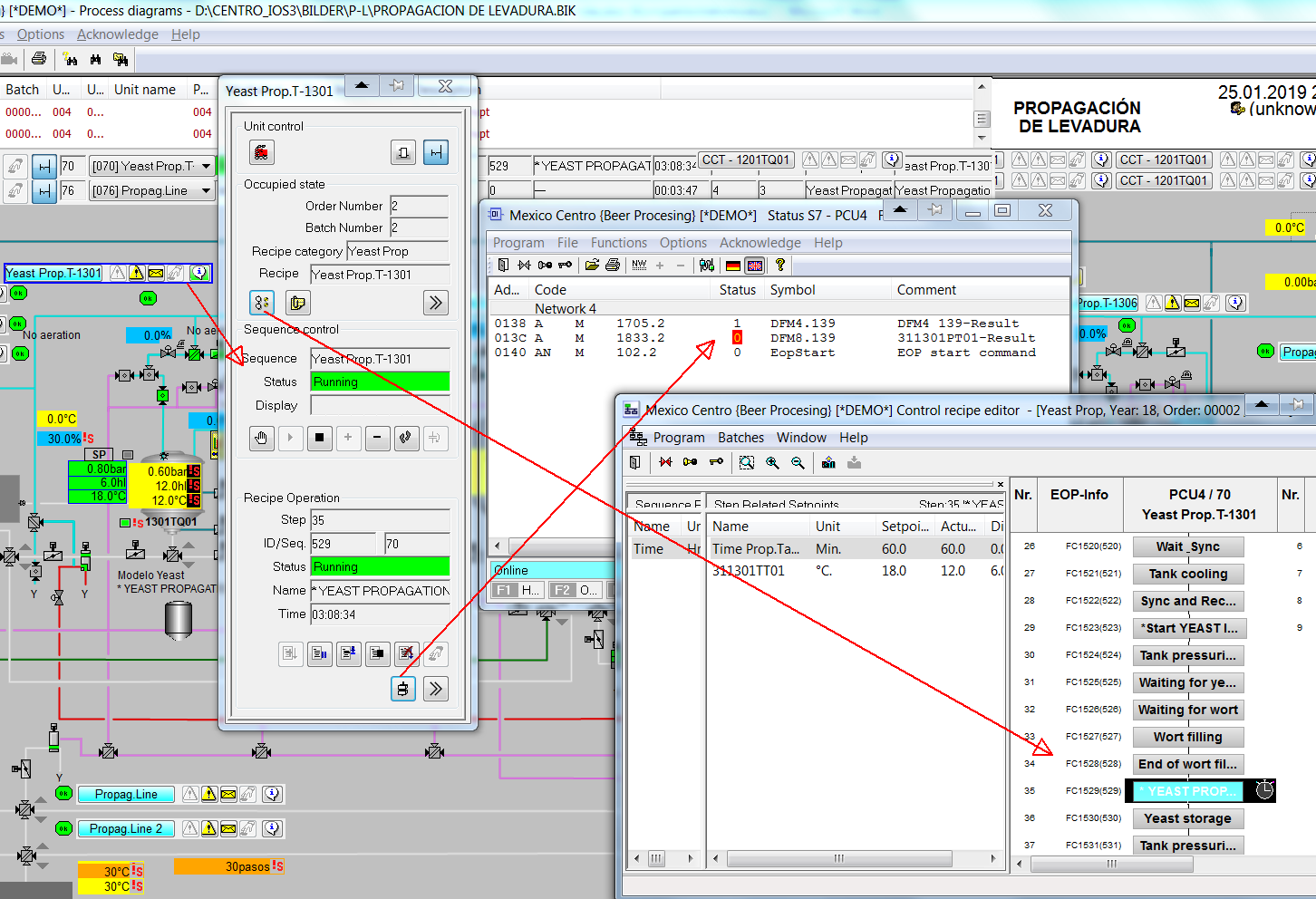

Control

If

you are in the online-view of Route control you can right click on a

element an jump in the picture where the element is located.

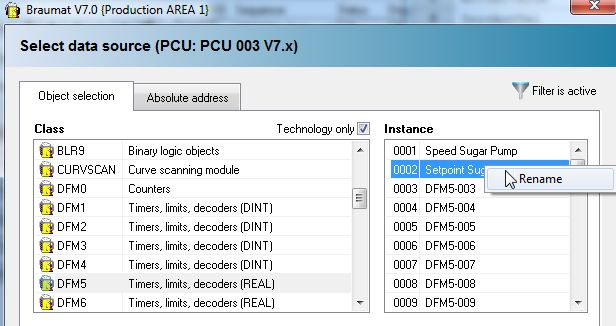

Parameterization

The

Instance-Name can be changed directly in here.

SQL-Server

To

activate SQL-Server in a Braumat-System a license must be installed.

Then in Site-Configuration, Server, „SQL-Server“ must be

checked. With click on that Button a window pops up and the address

of the partner can be adapted and data to be send to SQL.

On

the SQL-Server an Adapter-Software has to be installed to view and

adjust the Data going to SQL. On that Server MS-SQL-Software can be

installed for evaluation or Crystall-reports.

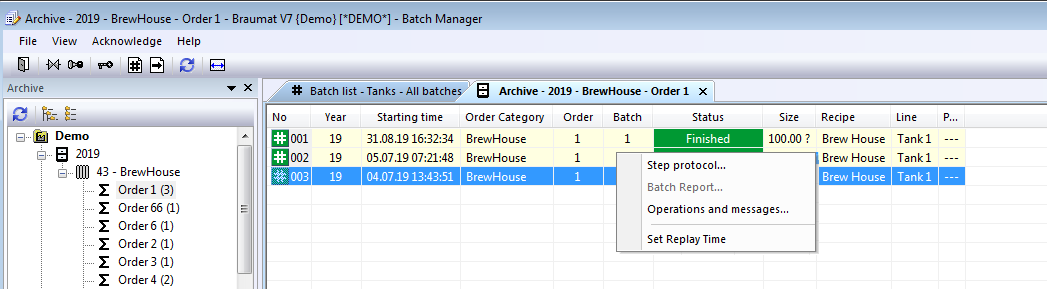

4Replay-Mode, Video-Mode

The

Video-Mode can be used from V7.1 SP1.

It runs as

well with old PCU-Version

V 5.3 or V6.0 etc.

It

has to be activated in the Site-configuration by “Log

Process-data” and “Show

Process-Data” at IOS and PCU!

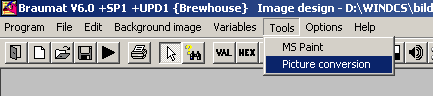

In

the Image-Design the Pull-Down-Menu “Tools”, get tags

for the recording-function“

has to be activated in order to get the necessary database. It

can be filtered which pictures are relevant for to be logged.

After

restart of Braumat in the PCU-Server, Display “coupling-status”

a S7-Logging-port is coming up and shows how many tags are logged.

In

runtime of the Process-Image, the Video-Mode can be activated by the

pull-down-menu.

In

the Order-System, history, Batch, right click a time-stamp can be

setup in order to start the according Video.

In

the Message-System, right click on a message a time-stamp can be

setup in order to start the according Video.

The

size of the Archive can be modified by the function

site-configuration, settings, “days for log”. 90 days

might be a reasonable value.

The

data can be stored on a separate disk.

4.1Seat lifting Block

In

order to use that function, an ICM must be defined as seat-lifting

block in the Parameterization. Then in the Picture this valve can be

setup as seat-lifting block.

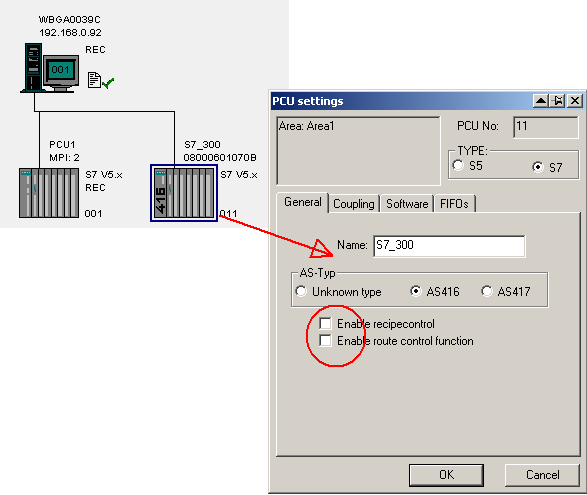

4.2Run Braumat with S7-300

You

can integrate a S7-300 to Braumat without the need to have any

Braumat-Software in the PLC. You can visualize all values in the

Graphics and change them.

Integrate

a new S7-416 with the Function Administration and configuration like

this:

Then

open the file \windcs\sys\area.ini and write “Sistar=0 “to

the PCU S7_300

[S7_300]

Name=S7_300

EnableRecipeControl=0

Family=S7

IP_Addr=192.168.0.2

l2_addr=2

SW_Recipe=V5

Sistar=0

Communication

can be by Ethernet or MPI!

4.3Monitor and control a S7-400-PCU with Braumat-OS without

Braumat-Software in the PCU

You

can integrate a S7-400 to Braumat without the need to have any

Braumat-Software in the PLC. You can visualize all values in the

Graphics and change them.

Integrate a new S7-416 with the

Function Administration, Configuration.

Uncheck

Recipe-control

Then

open the file \windcs\sys\area.ini and write “Sistar=0 “to

the corresponding PCU

[PCUx]

Name=remote_PCU

EnableRecipeControl=0

Family=S7

IP_Addr=192.168.0.2

l2_addr=2

SW_Recipe=V5

Sistar=0

4.4DFM-calls on FB100x is obsolete

With

this call “UC FB715” or UC “TA_CALL_DFM_FB”

the call of the FC736 etc. for DFM is not necessary any more.

In

Version V7.0 there the User-Block FC 2715 can be used.

4.5Telegram-forwarding to another Area (in Case only on Area has RCS)

Change

in PCU_serv.ini

[protocol]

30=PC-Name

of RCS-server; this has to be setup on NOT-RCS-server

...

36=PC-Name

of RCS-server; this has to be setup on NOT-RCS-server

Enable=1

Test

on RCS-server Window 2nd Tab

In

order to ensure RCS-Server switch over.

In

the Servers where no RCS is running

PCU_serv.ini

in Server X: the frist Server of the other Area

PCU_serv.ini

in Server Y: the second Server of the other Area

4.6Upgrade SQL to new version

Delete

Folder \Spooler.cis\dbf (it will be generated again!).

Test

SQL by

4.7Virtualization

For

installation use ISO-files or USB. But USB might be linked only to

one VMWare!! You have to remove always until you can connect it to

another one.

Upload/Download

right side Storage, right click “oben Files”.

Datastore

for ISOs and upload

Open

VMWare: open Console

CD-Symbol

for to mount ISO-File

Synchronize

pictures with other IOS

Please

set in Biko.ini:

CopyFilesToAll=1

4.8Change name of the IOS for display in the message-line

In the file

<projekt>\texte.0\ios.txt the names for Display in the messages

could be defined.

4.9RCS-Activation

Select

RCS in the Site-Config for the according PCU

Install

RCS-Software and insert in a new Database the PCUs you use

(ID=PCU-Nr).

Activate

RCS

Call FC820

TR_CE_ICM=TRUE

in FB1200, 1201, 1220,

1225

Change

in \Windcs\sys\pcu_serv.ini at Recipe-server, ports add

“RCS_PORT.DLL”

Call

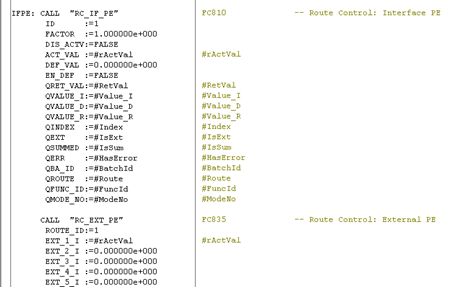

in FB100x

In

the FIFO (1 for Server 1, 4 for Server 2) add the telegram types

30,31,33,34,36

//no

way detected

U(

L

"SEQ".u.iROUT_ID

L

0

>I

)

U

"SEQ".uRCS.QREQ

U

"SEQ".uRCS.REQ

UN

"SEQ".u.CTRL.boRestart

S

"SEQ".u.CTRL.boPaused

//

RCS-Alarm --> stop recipe

U

"SEQ".uRCS.QERR

U

"SEQ".uRCS.REQ

UN

"SEQ".uRCS.ACK

S

"SEQ".u.CTRL.boPaused

//sequence

stopped

UN

"SEQ.RUN."

R

"SEQ".uRCS.REQ // Way off

R

"SEQ".uRCS.RON

SPB

r001

L

0

T

DB725.DBD 400 // Modes off

r001:

NOP 0

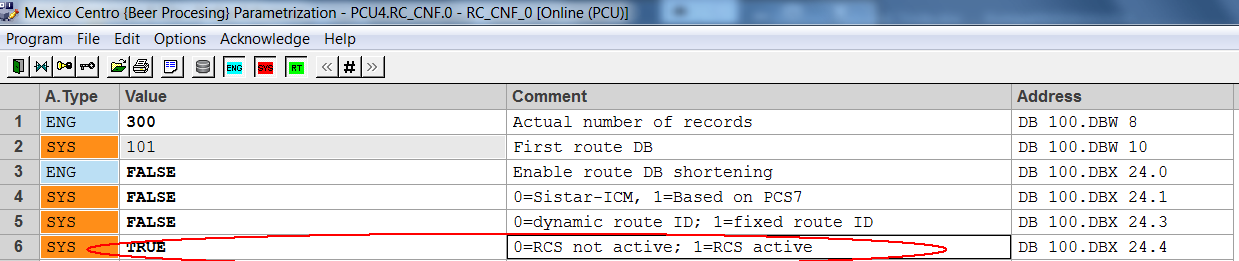

There

is a main-switch for RCS in RC_CNF_0 Global data

4.10How the performance of Braumat can be tested and increased?

Press

Strg (Ctrl) + Shift during opening a picture and the times are

displayed for all steps to open a picture.

Check the

Trace-Server for error-messages.

Ensure

the Network of the PCUs is physically separated from the network of

the IOS.

Check the

cables, Router and firewalls, to be correct.

The

fire-wall in the switches can slow down the network, maybe in the

Process-bus it is not necessary?

In

Site-Config: Link 50 % of the clients to Server 1 and 50 % of the

clients to Server 2. Open Site-configuration, Client, Tab Server

Sequences and select for one group Server 1 and vice versa.

Reduce

the number of open window in \Project\sys\sys.ini

;Maximum

account of SISTAR-Windows to a reasonable value maybe 7;

Reduce

the number of Sequences in the PCU to running sequences + 10 % in

parameterization, Sequences, Global data, number of…

Do the

same for PID, AVA, AOUT and ICM 1-4; Switch off complete ICM-groups

if not needed.

Take care

not to log the Analogue-Values to fast in the Trend-definition. For

temperature 10 seconds is enough etc.

Cross-Communication: reduce

number of Jobs (only one DB Send/Receive), reduce time for Jobs, 3-4

seconds,

Windows-Colours: Resolution high colour is

enough!

Put User-Functions in FB1225 1 sec. or

FB1001.....

Take a

look in Windows with the command “msconfig” which

programs are loaded during startup. All are really necessary? But

some services etc are necessary!

New S7

CPUs are faster. But in this case the CP has to be changed as well.

Most fast is the configuration that the communication is on the

CPU-module.

In

serious cases it is possible to let the Trend-Manager and curves run

only on one Server. In a virtual system, the logging of trends one

server is enough. Because a VM-Ware hardly crashed, only the

complete PC.

In the

Windows Task-manager you can see which programs take a lot of

performance.

In the

Hardware-Configuration the Network-Resources can be set to 50%. But

it will use only the Resources needed for communication (not 50!).

Ensure

that the virus-scanner are not working continuously over the

network.

Use ping

192.168.0.1 -t to request permanent responses. If there are

time-out, something is not correct on the network. The time should

be always <1ms

Use

tracert 192.168.0.1 to check all router and switches on

performance. There should be no time-out.

5The trigger for the curves does not work properly

Maybe some

trending from the wrong area are requested?

5.1How to have save Remote-Access on Braumat

In order to

have save Remote-Access on Braumat it is recommended to connect an

Office-PC to Internet and not

the BRAUMAT-Bus.

Remote

Access on this PC by Teamviewer, Cisco-Anyconnect, Sinema etc.

From this

Office-PC by (an extra network-card?) one Network-cable to

Braumat-PC, but a Firewall (Software or Hardware) in between.

Remote-Control

to Braumat by MS Remote Desktop or UltraVNC. File-transfer is

possible.

For more

security call prior to remote-session, plug in the cable and unplug

after finish session.

5.2How to integrate own functions in Braumat

In order to a

description for a DB in the Parameterization, open in \PCU.00x a

textfile with the extension .pcu

object

Name=DBxyz;(*Name*)

CID=1920;

max=128

offset=100;

length=100

number=DBW8;

filename=Name Textfile;

{

Number of (1,DBW8,I16,RD);

(*Number of*)

struct

Braumat_V7 (1, DBX43.7, B1)

(*Braumat_V7 = 1 read/write*)

Name (2,DBB4, I8);

(*Describion Integer 8*)

Word (3,DBW4, I16);

(*Describion Integer 16*)

Sequence (4, DBB0, ENUM_P:SEQUENCE,

0, 128) (*Sequencer Textfile from 0-128*)

ZSW, RT

(5,DBW16 , HEXA,RD ) (* ZSW Status word of Simocode Read only*)

}

ZSW, RT only display

ZSW, SYS only

display when button Sys

5.3How to use a Braumat V7-Reference

In Braumat V7

the address-pointer for a source is now 64 bit. In this way you can

get the address:

:

CALL

BmGetRefValDIntFC(Ref := u.refQDat, RET_VAL := xRetVal, Result :=

diValue);

//

Take value if it is valid

UN

xRetVal;

SPB

ERTA;

L

diValue;

T

#u.diValueAV;

L

#u.diValueSP;

==D;

=

#u.xResult;

ERTA:

SPA ENDE;

Important:

the consumer of the reference must know which data type he expects

for further use. If the above reference points to a REAL attribute,

for example, the BmGetRefValDIntFC automatically converts to DINT.

5.4How to get an old free protocol mdb-Database on new

Braumat-versions

Install

an office 2003 and convert the database to a new file. Rename this

file to MS to PI_charg32.mdb; Start MS-Access from the main-menu with

the database PI_charg32.mdb. Maybe some adaption might be necessary.

● Due to the changed license structure and the path

separation "System" and "Project" the integrated

MS-Access macros had to be adapted in the provided example MDB

"<syspath>\! BM_Proj\Access32\PI_CHA32.MDB" can be

adapted.

● Existing

project-specific MS-Access applications for "Free Protocols"

from earlier BRAUMAT versions must be manually upgraded with the

current MS-Access macros.

● The

full product MS-Access is required for this.

5.5If the Area-Selection disappeared

In Sys.ini

Section PC there is a switch ShowAreaDlg=1 or by starting the

Application and press Strg + Click;

5.6Align the Tag-Info

To

align the Tag-Info switch to Tag-Info and mark all and select edit,

Align Tag info

5.7Change PCU-number in Process-Images

In Version V6

the Tool BikoUpgrader.exe can be used.

In V7 it can

be done by replace-function: Replace PCU,2,x by PCU,2,y

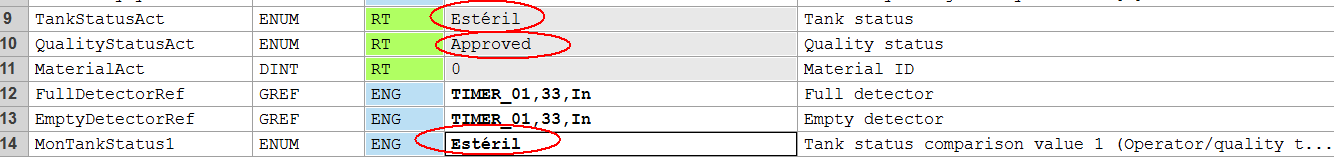

5.8TANK STATUS

In this way

the status of the Tank is displayed in the process-image and by click

more details are coming up.

L 1

//Status of the Tank according to the List..

T

"TANK".au[x].iTankStPv

SET

=

"TANK".au[x].xMonQualityOp //starting according

Monitoring-Times, but the tank needs to be in that Status!

R

"TANK".au[x].xMonCleanOp

R

"TANK".au[x].xMonSterileOp

The according

Status can be found in d:\Windcs\texte.x\TankStatus.txt

1 Clean

2 Sterile

3

Filling

4 Filled

5 CO2 preloading

6 Emptying

7 CO2 preloaded

8 Empty

9 CIP

10

Ready to fill

11 Ready to empty

12 Ready for CIP

More

=

"TANK".au[112].rQuantityTotal // Correct Total Tank

quantity

= "TANK".au[112].xSetMat // Set

Material value and Transfer Material-Number to Source

=

"TANK".au[110].xReset //Reset all

Only if line 9

and 14 are equal and it is Approved the Quality-Time will be started

Example for

Parameters

Note:

Tankstatus

can be changed directly in "TANK".au[1].iTankStatusAct and

the pulse for "TANK".au[1].xSetMat is not necessary.

That Impulse

will change the Brand as well, and that is allowed only when the Tank

is empty!!!!!

5.9Integrated delay-Time in EOP

Often a

delay-time is used to switch on something delayed etc. Braumat is

shipped with a delay-Unit for each unit or to have a minimum Time for

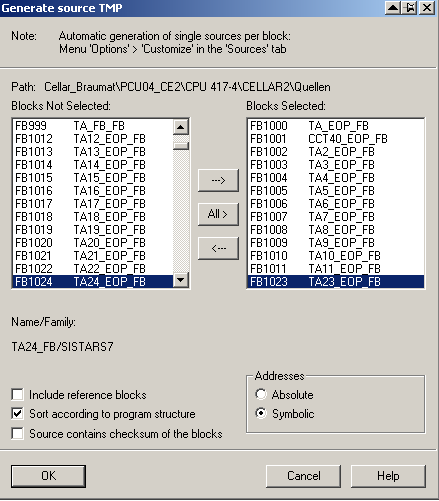

a Step.

Start delay time:

L 3 //Time in sec

T

DB725.DBW 184 // "SEQ".u.iSPDlyTm Setpoint Time

The

result-flag is M 101.1

5.10Free Recipe-based brew-report (from V8.0 on)

Single-value

(overwrite the same) or Multiple-value

Names and Unit

can be edited

also values

for the Units values can be defined.

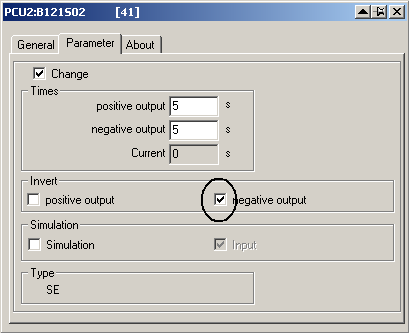

Esport /

Import to Excel is possible.

In recipe EOP

right click then list will pop up;

Setpoint or

actual-value

for each

Setpoint different Parameters

User-Id for a

User-defined value independent from EOP

RUP-Start /

Ende;

Order-System:

right Mouse-click -> Charge report

5.11How to make a monitoring-function?

In

order to switch on ICM from several Units ore making Sub-operations

you can program in FB 100x like that:

A "Unit106

DB".Bool48 //activation-flag

JCN end4

A

"DFM8.171"

= "312322XV07-CMD"

//action

end4: AN "Unit106 DB".Bool48

//reset at the end

FP "Unit106 DB".Bool108

//reset by pulse

R "312322XV07-CMD"

That

means in this way the output and flags can be activated from

different Units. <

Flag always

“1”

If

you need a flag which is always “1” take M 108.1;

Copy

a data-set in Parameters.

It

is possible to copy a dataset in the Parameters, with pull-down

“Edit” “copy to” or “copy from”

5.12Backup and Analysis (25.3.2019)

To ensure quality and safety,

a regular backup is mandatory. Maybe at the weekend when production

is down this is possible.

Braumat:

Transfer all DBs from PCU to IOS;

Simatic-Manager:

Backup all Blocks of all PCU.

New

cross-reference generated for all PCUs

CPU

Error-check all PCUs

Reorganisation

of the project

Clean

up not used folder

Compare

all online / offline

Check

Traceserver

To

get the faults, the I/O-Alarms of the CPU can be filtered by removing

at Setting “asynchronous” errors. And then the

program-errors pop-up.

6Not enough decoders? 11.2.2018

Especially if

Matrix function is used, decoders might not be enough. In that case

it helps to multiplex the Decoder that means to use the same

Decoder-number in parameters and to call FC 636 with the according

DFM directly before using the Decoder-flags.

Copy

/ Paste in Parameters

Is

possible, if it is the same Datatype!

6.1Recipe-System: Release a Unit and resume later on

Two batches

require subsystem 3 (e.g. heater) several times at different times in

their sequence.

subsystem 3

can released and used by subsystem 2, although it will be in recipe

subsystem 1 again at a later point in time and is required by it.

Subsystem 2 does not have to wait for Unit occupied in a different

recipe

enable this

function in the file "<proj-path\recipe\project\plant.ini":

[ReleasePlantSection]

Enable=1

A release Unit

step must be inserted in the basic recipe editor.

The release of

a plant section is only possible in two cases:

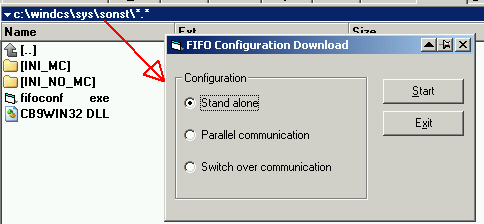

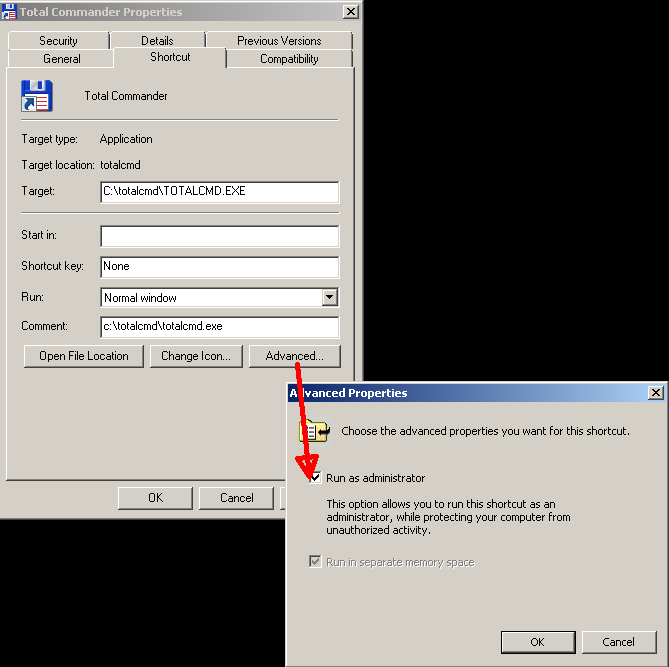

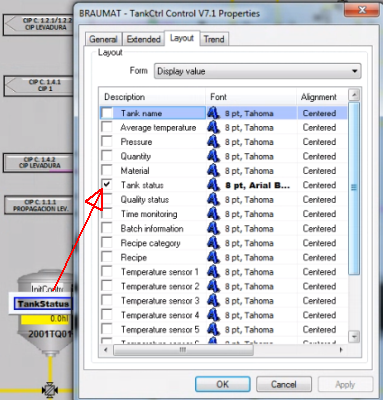

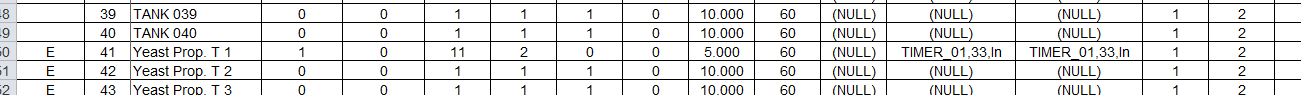

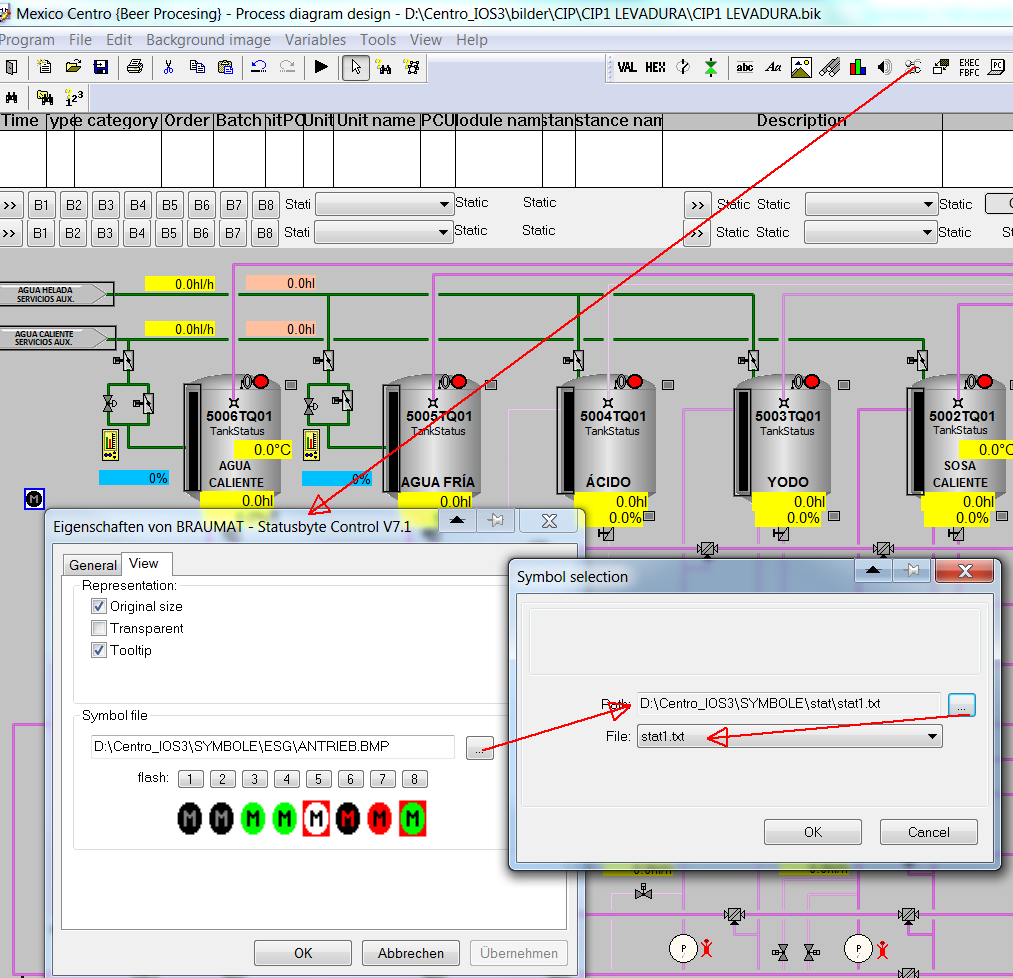

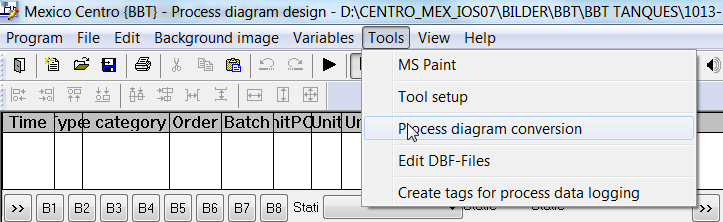

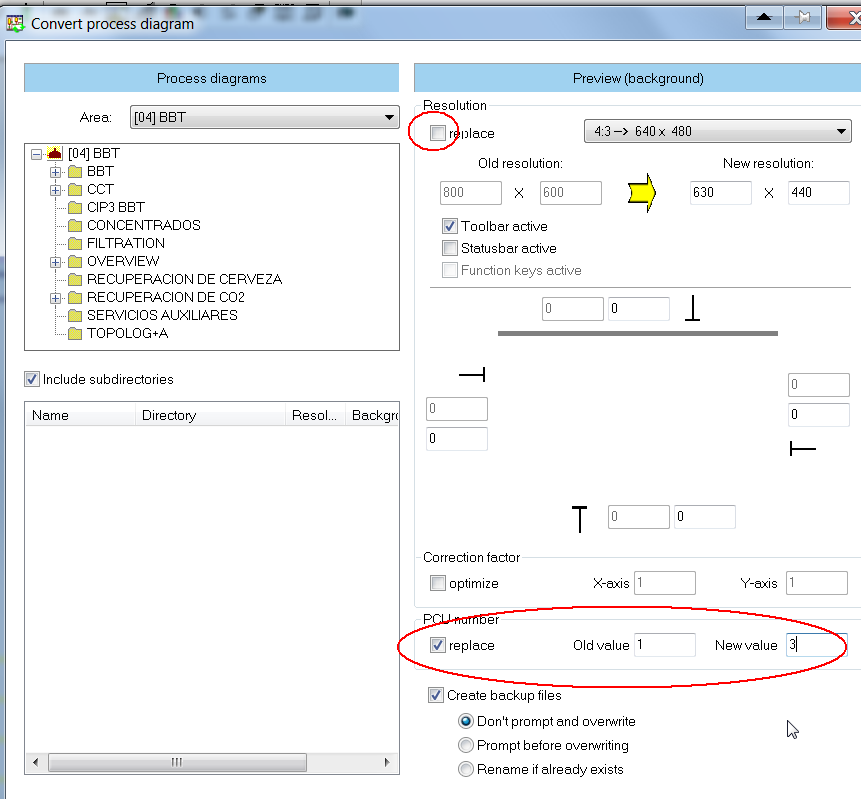

- There is a