|

Here you find some more Braumat-Tools.

Enjoy and give feedback! Thank you!

Best Time for implementing new Tools is during engineering. There is enough time to evaluate how it works and does it have some unwanted effect.

“Never touch a running system”, keep this in mind if you want to make new features during production.

Template for a Demo-System V6.0 SP2 with all Add-ons (see below) integrated

Braumat-Template V6.0 (can be easily converted to Version V7.x; to see all functions leave the foldername Windcs)

converted Template V7.x (leave the folder of Windcs) Download

with all applications and 2 no Braumat-PCU

Step7 is in \S7

PLCSIM in \Windcs\plc1.

MTK-Programm as a Template for Braumat-Programming with Basic-Functionality (in the above File)

Info

Excel-Describtion

Add-ons

Warranty and liability

The Application Examples are not binding and do not claim to be complete regarding the circuits shown, equipping and any eventuality. The Application Examples are intended to provide support for typical applications. You are responsible for ensuring that the described products are used correctly. When using these Application Examples, you recognize that we cannot be made liable for any damage/claims beyond the liability clause described. We reserve the right to make improvements to these Application Examples. We cannot give any liability for the information contained in this document.

Danfoss VLT-Drives including Danfoss Softstarter Braumat-Plug-in

Features

- Control of Danfoss VLT-Devices by Braumat with ICM-Group and number

- Additonally Control of the Danfoss VLT-Device by a flag-Byte

- Transfer of the Setpoint direct from Braumat Data-Sets like PID, DFM etc

- Transfer of Feedback and Alarm to according Braumat-Flags

- Acknowledge Alarm by Faceplate or global Acknowledge

- Display of the calculated current in the Data-Set

- Support for Danfoss-Softstarter

Download

Logfile for changes

Status: in use, runs on S7-400 and S7-1500

Siemens Simocode-Module Braumat-Plug-in

Features

- Control of Simocode-Devices of Siemens by Braumat with ICM-Group and number

- Additonally Control of the Simocode-Device by a flag-Byte

- Transfer of Feedback and Alarm to according Braumat-Flags

- Acknowledge Alarm by Faceplate or global Acknowledge

- Display of the calculated current in the Data-Set

Download

Status: implemented in Ursus Breweries, Romania

Profibus-Diagnostic by Braumat

With this module you get the Alarm-Messages from Profibus-Modules

Features

- Check Siemens and other Vendors Profibus-Modules for Alarm

- Process-Image for Display available

Download

Status: tested in Ursus Breweries, Romania but not used at the moment

Intervall-Timer with 32 Setpoint on/off, Enable-Mask and much more

Details:

Braumat is missing a function for Pulses for example for the flushing of different CIP-Valves or for a cascaded switch on of the Malt-Transport and other purpose.

This new Pulse-Generators has following Features

- Up to 32 different Set-points for Pulses switch on and 32 different Set-points for Pulses switch off.

- Up to 32 Outputs with minimum one Output with a defined on/off-Time.

- Start-Input, Hold and Reset-Input

- Additional you have a enable-flag for each Pulse. Thus interlock in the Malt-Transport can be realized (Stop starting-up in case of Fault)

- Additional you have a Mask for to disable each Pulse and go to the next one

- Can work in normal Mode (one by one)

- With overlapping of the Outputs (for to avoid noise during CIP). The overlapping-Time can be changed.

- It can switch on all Outputs cascaded (Outputs remains on) for example to switch on the Malt-Transport one by one.

- After switch on all Outputs it can switch off all Outputs one by one; There is a extra Time for to switch off.

- Open Source for own improvements

Download

Status: implemented in Ursus Breweries, Romania

Tank-Temperature-Control with BRAUMAT

Features of the Tank-Temperature-Control-Module

- max. 8 Zones

- max. 8 Sensors

- max. 8 Temperature-Controller with Hysteresis and Pre-Stop-Value

- Level-dependent Zone-Selection

- Level-dependent Temperature-Sensor-Selection

- Free selection Temperature-Sensors to Zones

- Auto-Select Zones at fermentation: top-Down

- Auto-Select Zones at storage: button-up

- Setup of Minimal Number of Zones

- Optional one additional Level for emptying of the Tank

- Setpoint-Ramp defined by Actual Temperature, Setpoint and Time or by Temperature increase / decrease per hour.

- The lowest cooling zone is monitored to avoid freezing

- The lowest cooling zone is monitored for deviating too high and too low and a Alarm is generated

- There is an Alarm for Max-Time fermentation and germination

- There is an Alarm for Max-Time Storage

- There is an Alarm for Max-Time CIP

- There is an Alarm for Max-Time Sterile

- There is a Summary Alarm Flag

- There is a Summary Reset Alarm

special Features

- Tank-Status with max. 255 entries independent from the Step

- Number minimal Zones for Auto-Select Zones at fermentation

- lowest Zone on during fermentation?

- All Data can be modified by Braumat Parameterization

Download

Status: implemented in Wuerzburger Hofbraeu and Ursus Breweries, Romania

runs on S7-400 and S7-1500

Tank-Data-Management-Functions

Up to 10 Dataset for max. 10 Brews are stored and displayed with

- Sort

- Quantity

- Total Quantity

- Brew-Number

- Batch-Number

- Tank-Status

- Max. number of brews in the Tank and actual Brew-Number

- Download

- Status: implemented in Wuerzburger Hofbraeu and Ursus Breweries, Romania, but lots of improvement since.

Selected Tank is empty

Small Tool to check that the selected tank is empty or fill (CIP etc).

Download- Check the flushing-quantity for each Tank by the Tank-number

Download

Silo-Data-Management

Features

- Completely standalone application, no changes to the necessary steps etc.

- graphical programming and display by process-picture

- Overview-picture with up to x Silos and all Data

- Manual correction of all Data

- Calculation and actual display of content as bar

- Data Management with up to 10 additional data:

- Ø Malt_Type

- Ø Delivery_Number 1-3 (3 fillings)

- Ø Supplier 1-3 (3 fillings)

- Ø Betaglucan

- Ø EBC

Download

Status: implemented in Ursus Breweries, Romania

Status: runs on S7-400 and S7-1500

Ramp-Function by Time and Delta x / min

(For Temperature, Pressure-Controller etc)

Regulating the Steam-valve by increasing the Temperature only 1°C/min saves a lot of energy and is good for the product.

This function can work in two modes

Linear Mode

Calculation by Start-Value, End-Value and given Time

Ramp-Mode

The Setpoint-Temperature is increased by °C / min which can be input by DFM. It starts with the actual value which is increased by °C / min.

Download

Status: implemented in Ursus Breweries, Romania

Braumat SE-Timer

With this modification the Timer can generate a Delay on and Delay off Pulse at the same time.

Download

Status: tested

Average-calculation

Sometimes a measured value is quite unstable. With this Tool you can make a Average-calculation; It can be all second or any defined time. It can be external triggered by SQL-Data. Up to 20 values..

Download

Status: in use, runs on S7-400 and S7-1500

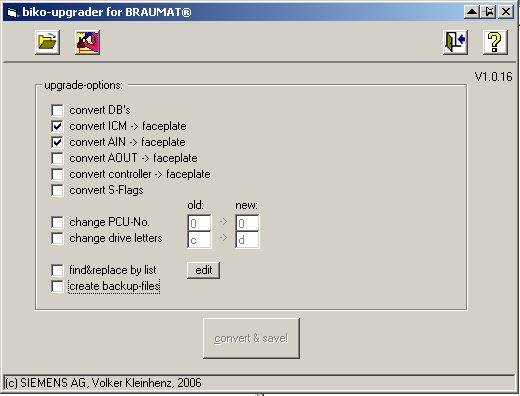

Biko-Upgrader

A tool to upgrade automatic old ICM-FAceplate to new Version, old Analogue-Faceplate to new Version,

Change PCU-Number, Drive C: to D: and reverse and many more.

Download

Status: used for many upgrades; For controls change of PCU-number has to be done manually by

search for PCU,2,x and replace by PCU,2,y in the *.bik-file

Symbol-Library ICM and Flags?

There is not very much Symbolic shipped with a new System. Here is more

Download

Status: in use, runs on S7-400 and S7-1500

Datalink-OCX

Unfortunately no more official Element of Braumat-CD but very usefull to access the S7 by Visual Basic etc.

With Datalink OCX you can upload and download Flag, DB, Input, Output outside Braumat, but the PCU-Srver need to be active

Download

Status: used in several applications.

Double Seat Valve

Double Seat Valves are frequently used in Breweries, especially in the cellar-area. Here you find a applicative solution for to handle that with Braumat.

Download

Status: in use, runs on S7-400 and S7-1500

Sequence-Add-on

Activation of the outputs, operator-request, messages, adapting the next-step-conditions and more without programming, realized by a process image

Modifying ICM-activation and Transitions requires a programmer. With this feature you can modify a lot of Braumat-elements in the Steps and outside.

Download

Braumat Data-base-generator for free Protocols with Excel-Evalation based on Templates

Short presentation of the functionality

Solution for to extract Process-Data at dedicated Steps as a basis for a Brew-Report and for a Database on the Computer.

If the SQL-Database Braumat driver is installed this Data will be integrated in the SQL-Data-Base as well

Download

Status: in use, runs on S7-400 and S7-1500

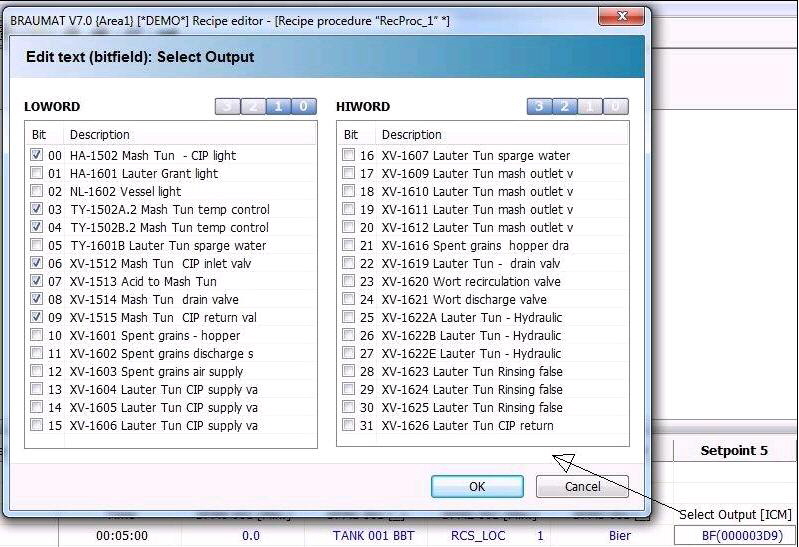

Recipe-based Process-Control for Output and Transition

This function offers the possibility to modify the Outputs in the Step and the Next-Step-conditions using the recipe-System and the Binary-functions “Bitfield”.

Features

-Evaluate a Binary Bitfield-DFM to activate the according output.

-Evaluate a Binary Bitfield-DFM to display a feedback of a output.

-Evaluate a Binary Bitfield-DFM to activate the according Flag (Message etc).

-Evaluate a Binary Bitfield-DFM for to check the next-Step-conditions by flag (DFM / Input / ICM-Feedback)

-Check for True / False.

-Check for “AND” and “OR”.

-Maximum 8 DFM

-A Operator-request can be activated combined with other conditions.

-The function can be used parallel to a Step7-programming with priority Add-on or programming.

Download

Recipe-based Process-Control for Output and Transition if the ICM and DFM are not in a block

Recipe based activation of Actuators and modification of transitions ensure high flexibility to adapt the process to specific needs. It gives the operator transparency about the action of the specific step and the Transition-conditions.

Features

Template with 2 DFMs using Decoder 1 and 2;

32 Outputs, ICM or more can be activated by recipe

Operator-request can be activated

Transition: 8 DFM with compare > or <;

16 more additional functions like Message etc

Download

Weighing with Braumat and Siwarex FTA

Braumat with Energie-Monitor PAC 3200

Download

Saving energy by Load-shedding

Almost all small and medium-sized enterprises, when their connection power exceeds x kW (depending from the power supplier), have to pay a higher price in addition to the working price. An energy peak within a measuring period beyond the agreed power supply limit can increase the electricity cost for the entire year drastically.

With this function, it is possible to deactivate different units independently, depending on the energy

consumption. This allows the customer to easily implement a load shedding system and to save energy

and reduce costs.

Up to 32 Units can be managed independent.

32 outputs can be freely defined for 32 units.

Each output-function can be activated and deactivated individualistic.

Freely programmable priorities for the devices for load shedding

Additionally an output-flag can be defined in order link the function with a subsequent module

for additional logic.

2 digital inputs for the energy-counting pulse and for the synchronization impulse.

The measuring pulses have a variable ratio (for example, 1000 pulses / kWh)

The measuring period or synchronous pulse is variable, usually every 15 min.

Minimum switching-on time as well as maximum switch-off times for each output.

The timing of a measuring period is set by the power-supplier via a synchronous pulse. If not

existing an internal timer can be used.

If the contact closes for at least 150 ms, it is recognized as a synchronous pulse and the

measuring period is restarted.

Download

Universal-Function for Energy-optimization and any switching function

To reduce the Energy-demand this function can be used.

Any numbers of Modules are possible, depending from the DB-length.

•Each module has a weekly program Off, all day, Monday-Friday, Monday-Saturday, Sat/Sunday, only Sunday.

•For each module one Time-Program can be defined (from… till).

•Several modules can work on the same output, so different time-slots are possible.

•For each output an analog Input can be defined with a Setpoint, Hysteresis and compare on “>” or “<”. This can be for example a Light Sensor in case of illumination or a Temperatur-Sensor etc.

•For each module a Digital Input (Sensor) can be defined for to activate the output.

•For each module another Digital Input (Sensor) can be defined for to switch off the output.

•For each module an Output can be selected freely.

•The Status of the Time-Function, Analog-Input and Digital Input is displayed.

•The functions of Time-Unit, Analog-Input and Digital Input can be cascaded or used individually.

•Each output can be switched on manually

•The modules can be linked with each other (cascaded).

•No additionally programming is necessary.

•All necessary Text can be input directly in the application.

•This module can be combined with the function load-shedding.

•The output can be used in several modules and parallel to other User-programming in the PLC (OR-Logic).

Download

Automatic generation of the Step7-Symbolic-File from the Excel Energineering-Template

see last Tab for the Symbolic-File

Download

Status: in use, runs on S7-400 and S7-1500

DFM-Call in FB100x obsolete

With this call “UC FB715” or UC “TA_CALL_DFM_FB” the call of the FC736 etc. for DFM is not necessary any more.

In Version V7.0 there the User-Block FC 2715 can be used. (see Download)

Download

Status: in use, runs on S7-400

Monitor and control a S7-400-PCU with Braumat-OS without Braumat-Software in the PCU

Run Braumat with S7-300

Download

Softcell: Universal-Module for Braumat

Customized software is very expensive and often not very flexible for changes or adjustments.

To save engineering costs and to give the customer more flexibility and transparency, this universal module has been created.

It offers the possibility to realize a variety of different functions without having to program it by a process image. Also in the field of energy-management.

The function work parallel to the sequential control but is the Master for the Output. That means additional functions can be realized (conditional set, reset of an output) influencing the same Outputs like in the sequential control.

Download

Excel-Template to generate Braumat-Code

based on a Matrix-Describtion. This can speed up Engineering drastically and increase transparency

Download

Status: in use, runs on S7-400 and S7-1500

Excel-Template Samples for different Areas

Download

Status: in use, runs on S7-400 and S7-1500

Replace Code by a list

in order to Clone Units it could help to replace Merker and Tags by a list.

With that Word-Macro it might be possible.

Download

List actual messages, message high Score, which ICM is in Simu, which without Interlock

In Braumat the messages are in a buffer and old messages not easy to find, if they happened some time ago, So although some is still in Alarm, the message is not visible. To avoid that this Message-Picture was created to show all actual Alarms.

Furthermore the ICM with the most Alarms are displayed.

All ICM which are in Simulation or forcing enable are listed as well

Download

Status: in use, runs on S7-400 and S7-1500

Route-control engineering by Excel and Import partial routes

Download template

dBase-File Editor

New Office-Versions > 2003 cannot manage dBase-Files anymore, but Libre-Office can do that. So a useful Tool to edit and modify dBase-Tools for Braumat. Libre Office is license-free also for commercial and industrial purpose.

free Download

The Total-commander with dBase-Editor plugin. can edit dBase-Files as well.

free download

More

Access Simatic S7 by Visual-Basic and TCP/IP.

Access Simatic S5 by Visual-Basic;

Access PLCSIM by Visual-Basic. Software and Source-Code

|